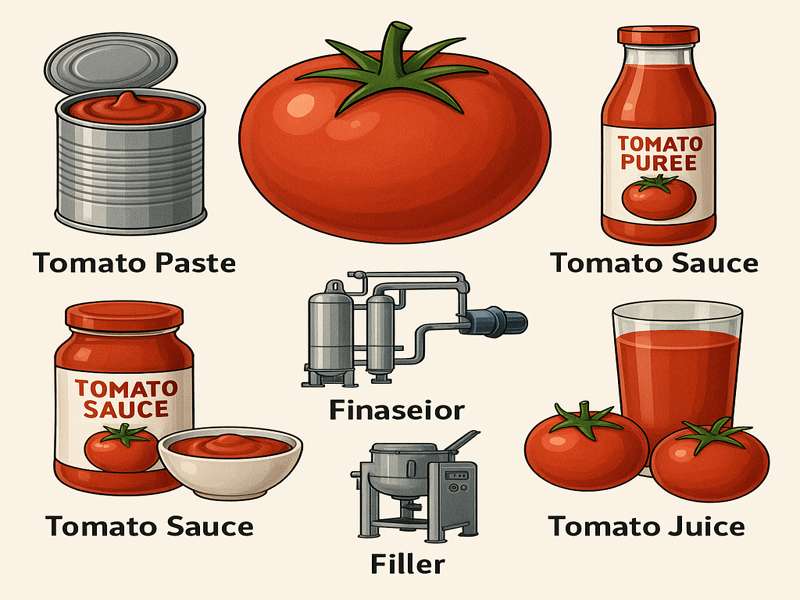

Tomatoes are the heart of countless food products—from concentrated pastes to refreshing juice. But while the raw ingredient is the same, the processing equipment varies significantly depending on the desired end product. Whether you’re planning to produce concentrated tomato paste, puree, tomato sauce, or tomato juice, choosing the right machinery is critical for efficiency, taste, and product stability.

Tomato Paste Processing Equipment

Product Profile

Concentrated tomato paste typically has a Brix level between 28–36%, making it a shelf-stable, long-life product commonly packed in aseptic drums or pouches.

Core Equipment List

Hot Break System: Maintains enzyme activity for better thickness.

Crusher and Pulping Machine: Breaks down fruit and separates seeds/skins.

Multi-Effect Evaporator: Reduces water content using falling film or forced circulation technology.

Aseptic Sterilizer & Filler: Ensures microbial safety and long shelf life.

Key Features

Ideal for industrial use and bulk export.

Requires high thermal stability, precise Brix control, and microbial inactivation.

Tomato Puree Processing Equipment

Product Profile

Tomato puree is less concentrated (typically 8–12% Brix) than paste and retains more of the tomato’s natural flavor and color. It’s often used in soups, ready meals, or as a semi-processed ingredient.

Core Equipment List

- Cold or Hot Break System: Cold break preserves color, hot break increases viscosity.

- Pulping and Refining Machine: Separates skin and seeds with gentle processing.

- Single-Stage Evaporator (Optional): For slight concentration.

- Pasteurizer and Filler: Ensures microbial safety with gentle heat treatment.

Key Features

- Gentle thermal treatment for better color and freshness.

- Often packed in cans, bottles, or aseptic pouches for mid-shelf life.

Tomato Sauce Processing Line

Product Profile

Tomato sauce typically includes added ingredients like sugar, salt, vinegar, and spices, with Brix levels of 18–22%. Texture and taste uniformity are key for market success.

Core Equipment List

- Pre-mixing Tank: For mixing dry ingredients and liquids.

- Cooking & Blending Kettle: Applies heat and agitation to blend the ingredients evenly.

- Homogenizer: Ensures a consistent, smooth texture.

- Hot Filling Machine: Bottles or packs sauce at elevated temperatures to extend shelf life.

Key Features

- Focuses on recipe control, viscosity, and texture uniformity.

- Requires flavor retention during heating and packaging.

Tomato Juice Processing Line

Product Profile

Tomato juice is minimally processed and often consumed fresh. It has a low Brix value (5–8%) and requires light heat treatment to retain nutrients and flavor.

Core Equipment List

- Cold Break Crushing System: Preserves natural enzymes and nutrients.

- Juice Extractor & Centrifugal Separator: Removes pulp solids while keeping the juice clear.

- Flash Pasteurizer: Gentle thermal treatment for safety without flavor loss.

- Bottle or Carton Filling Line: Aseptic or hot filling for shelf-stable packaging.

Key Features

- Designed to preserve color and nutritional value.

- Used in beverage plants or multi-line juice production facilities.

Comparison Chart: Tomato Processing Equipment at a Glance

| Product Type | Brix Range | Break Type | Evaporation | Special Equipment | Typical Packaging |

| Tomato Paste | 28–36% | Hot Break | Multi-effect evaporator | Aseptic filler, forced circulation evaporator | Drums, pouches |

| Tomato Puree | 8–12% | Cold/Hot Break | Optional single-stage | Pulp refiner, pasteurizer | Cans, bottles, pouches |

| Tomato Sauce | 18–22% | Hot Break | Optional | Mixer, cooking kettle, homogenizer | Bottles, sachets, pouches |

| Tomato Juice | 5–8% | Cold Break | None | Juice extractor, separator, flash pasteurizer | Bottles, cartons |

Why This Matters for Your Tomato Processing Plant

Knowing these distinctions can assist you when starting or expanding a tomato processing facility:

- Select the right line layout and machine configuration

- Avoid equipment overinvestment or underperformance

- Ensure product quality matches market expectations

- Boost operational efficiency and minimize waste

Each product type requires specific processing logic. For example:

- Tomato paste demands evaporators and aseptic fillers.

- Sauce lines need blending tanks and recipe formulation.

- Juice relies on extractors and light pasteurization.

Turnkey Tomato Processing Line Solutions

As a professional tomato processing equipment manufacturer, we provide:

- Custom solutions for any product type or capacity (1–50+ tons/hour)

- Turnkey tomato processing lines from reception to final filling

- In-house design, 2D/3D plant layout, installation, and operator training

- CE/ISO-certified machines with full after-sales support and spare parts

Whether you’re producing one product or multiple SKUs, we help you build the right plant from the ground up.

📞 Ready to Build Your Tomato Processing Line?

Looking to produce tomato paste, puree, sauce, or juice? We’re here to help. Our experts can analyze your needs and recommend a tailored solution—from single machines to full-scale lines.

👉 For a free consultation and personalized plant layout, get in touch with us right now.