Tomato Processing Equipment Manufacturer

- We are a professional tomato processing equipment manufacturer with many years of experience in manufacturing food processing equipment, providing advanced tomato processing equipment to help you produce high-quality tomato products that meet your needs.

- Our custom tomato processing machines serve global sauce makers and food producers, offering turnkey equipment and full production support.

- High-quality equipment built from stainless steel.

- Full support for training and commissioning.

- After-sales service and support.

- Excellent Tomato Paste Sterilization

What Machine Does Our Tomato Processing Line Provide?

As a tomato processing equipment manufacturer, we provide efficient, hygienic, and scalable machines for every stage—from raw fruit intake to final packaging.

Fresh Fruit Receiving and Pre-processing

Wash, inspect and sort fresh tomatoes to ensure clean, high quality raw materials for processing and protect downstream equipment.

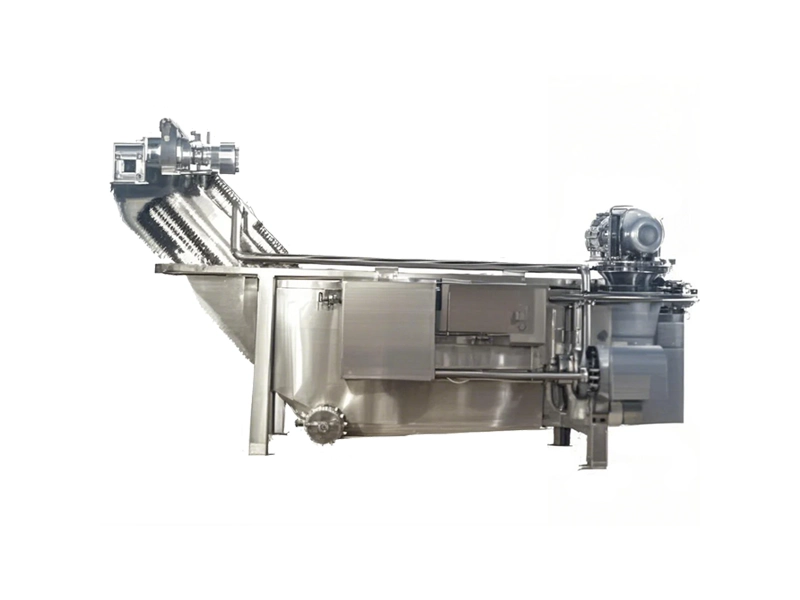

Fruit Washing, Sorting, Lifting Monobloc

This integrated unit performs three essential functions—washing tomatoes to remove soil and debris, sorting to eliminate damaged or unripe fruit, and lifting the cleaned tomatoes for transfer to the next stage. It ensures clean, uniform raw materials and smooth upstream processing.

Tomato Paste Extraction and Refining

Use hot or cold crushing systems to achieve specific viscosity and color and refine tomatoes to produce a smooth slurry for high-volume, consistent tomato paste production.

Required Equipment

- Fruit Receiving Hopper

- Crushing & Transferring Pump With Thruster

- Tubular Preheater

- Peeling, Pulping And Refining Machine

- Operation Platform

- Raw Tomato Paste Storage Tank

Crushing & Transferring Pump with Thruster

Crushes tomatoes into pulp and pumps the mixture into the preheater or pulper. In addition to preventing clogging or the separation of materials and liquids, the thruster guarantees steady movement.

Preheating Tubular

Crushed tomatoes are heated quickly to deactivate enzymes and maintain texture and color. It prepares the mash for efficient pulping and better paste yield.

Peeling, Pulping, and Refining Machine

The pulp is extracted, leaving behind the seeds and skins. Refines the product into a smooth slurry by filtering solid residues, ensuring a uniform consistency for concentration.

Vacuum Evaporation

Tomato pulp is concentrated into a paste using vacuum evaporation, retaining color, flavor and nutrients while achieving the desired Brix concentration(e.g., 28–30%, 36–38%) using an energy-efficient Italian multi-effect system.

Required Equipment

- Scrape Type Vacuum Evaporator

- Product Mixing/ Sterilizing Tank

- Brix Control System

- CIP (Clean-in-Place) System

Scrape Type Vacuum Evaporator

Concentrates tomato slurry into paste under reduced pressure. The scrape mechanism prevents fouling on heat exchange surfaces, ensuring thermal efficiency and consistent Brix control.

Product Mixing/Sterilizing Tank

Combines paste uniformly and heats it to sterilizing temperatures, ensuring microbial safety before packaging. It balances quality, texture, and shelf stability.

Downstream Filling and Packaging

The concentrated paste is filled into a variety of containers using an aseptic system to ensure long shelf life, safe storage and ready for shipping or retail.

Required Equipment

- Pouch Forming-Filling Seaming Coding Monoblock

- Viscous Product Filling Machine

- Semi-Auto Capping Machine

- Manually Drying, Casing

- Handle Ink Code Printer

Pouch Forming-Filling-Seaming-Coding Monoblock

An all-in-one system that forms pouches from film, fills them with paste, seals them, and prints batch or date codes. It offers speed and precision for high-throughput pouch packaging.

Viscous Product Filling Machine

Accurately dispenses thick tomato paste into containers like bottles or jars. Designed for high-viscosity flow, it ensures clean, drip-free operation and precise portioning.

Semi-Auto Capping Machine

Applies caps to filled containers with manual or semi-automatic control. It provides secure sealing to prevent leakage and contamination while improving packaging speed.

End Product Types of Tomato Processing Line

Here’s a professional comparison of the various product formats, highlighting their key differences in processing level, Brix, texture and application:

| Product Type | Brix (%) | Texture | Flavor Intensity | Processing Level | Usage |

| Tomato Paste | 28–38 | Very thick | Very strong | Highly concentrated | Industrial, retail paste, repacking |

| Tomato Puree | 8–12 | Smooth, thick | Medium | Moderately concentrated | Sauces, soups, stews |

| Tomato Sauce | 8–16 | Pourable | Flavored | Final product with recipe | Ready-to-eat, culinary sauces |

| Tomato Juice | 4–7 | Thin, fluid | Mild | Minimal concentration | Beverage, soups, mixes |

End Product Package Forms of Tomato Processing Line

Small Bags / Sachets (5 – 70g)

Single-use tomato sauce or puree packs. Uses Pouch Forming-Filling-Seaming Monoblock and heat sealer. Cost-effective and convenient for fast food, takeout, or retail promotions.

Cans (100 – 2500g)

Retail-ready packaging for paste, puree, or sauce. Needs viscous filler, retort sterilizer, and seamer. Durable, shelf-stable, and widely accepted for household and foodservice use.

Aseptic Bags (5 – 1000kg)

Used for bulk packaging of tomato paste or puree. Requires aseptic filler, vacuum evaporator, and Brix control. Ideal for industrial use and long shelf life.

FAQ

What types of tomato processing equipment do you manufacture?

How can I pick the best tomato processing line for my manufacturing facility?

What is the capacity range of your tomato paste production lines?

What’s the difference between cold break and hot break tomato processing?

Do you provide turnkey tomato processing plant solutions?

What materials are your tomato machines made from?

Do you offer filling and packaging systems for tomato products?

Which post-purchase services are available for tomato processing lines?

Describe Your Project to Us

Maximize your palm oil production and quality with our complete list of production equipment, from fruit receiving to final oil pressing.