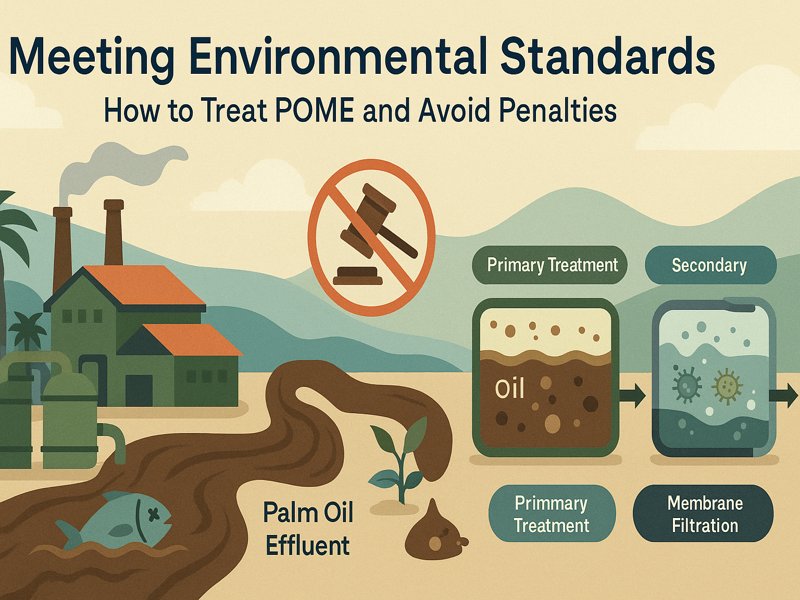

Palm oil mill effluent (POME) is a major environmental concern as production rises to meet global demand. If untreated, it can damage ecosystems, pollute water, and result in legal penalties. Effective POME treatment is essential for compliance, sustainability, and profitability.

Understanding POME: What It Is and Why It Matters

POME is a thick, brownish liquid waste generated during palm oil extraction, primarily from sterilization, clarification, and hydrocyclone operations. About 2.5 to 3.5 tons of POME are produced for every ton of crude palm oil (CPO).

Key Characteristics of POME:

- High COD (Chemical Oxygen Demand): 45,000–100,000 mg/L

- High BOD (Biochemical Oxygen Demand): 20,000–50,000 mg/L

- High Total Suspended Solids (TSS): 18,000–50,000 mg/L

- Acidic pH: Typically around 4–5

- High oil and grease content

These characteristics make POME one of the most polluting agro-industrial wastewaters. Without adequate treatment, POME discharge can cause oxygen depletion in water bodies, fish kills, and severe soil and groundwater contamination.

Environmental Regulations Governing POME Disposal

Many palm oil-producing nations have enacted stringent laws to regulate POME discharge. These standards aim to prevent environmental degradation and promote sustainable industry practices.

Malaysia:

The Department of Environment (DOE) mandates that final POME effluent must have:

- BOD ≤ 20 mg/L before discharge into inland waters

- Additional standards for TSS, oil & grease, pH, and ammoniacal nitrogen

Indonesia:

The Ministry of Environment and Forestry enforces limits such as:

- BOD ≤ 100 mg/L

- COD ≤ 350 mg/L

- More lenient than Malaysia, but tightening with international sustainability pressure

Colombia, Thailand, Nigeria, and Others:

Countries increasingly align with RSPO (Roundtable on Sustainable Palm Oil) and IFC environmental guidelines, pressuring producers to invest in effective effluent treatment.

Penalties for Non-Compliance:

- Fines ranging from $5,000 to $100,000+

- Plant shutdowns, license suspension, or imprisonment

- Reputational damage and export bans from sustainability-conscious markets

Primary Methods for Treating POME

Various technologies are available to treat POME, depending on discharge requirements, mill capacity, and investment capabilities. Treatment typically follows a three-stage process: primary, secondary, and tertiary treatment.

Primary Treatment: Physical Methods

- Used to remove large solids and oil.

- Screening: Removes coarse solids (fibers, nuts)

- Oil & Grease Traps: Skim floating oil for recovery

- Settling Pits or Sedimentation Tanks: Separate heavier solids

Advantage: Simple and low-cost

Limitation: Cannot remove dissolved organic pollutants

Secondary Treatment: Biological Methods

Targets the high BOD/COD levels using microorganisms.

Anaerobic Digestion (Most Common):

- Uses anaerobic ponds or closed digesters

- Converts organic matter into biogas (CH₄, CO₂)

- Retention time: 15–60 days

Advantages:

- Biogas can be captured for electricity (up to 28 m³ per m³ of POME)

- Low operational cost

Limitations:

- Large land footprint (for ponds)

- Sensitive to pH, temperature, and overload

Aerobic Systems:

- Includes activated sludge, oxidation ditches, or trickling filters

- Requires air/oxygen injection

Advantages:

- Faster degradation

- Can reach BOD < 20 mg/L

Limitations:

- High energy and maintenance costs

- Not suitable for all locations due to power needs

Tertiary Treatment: Polishing the Effluent

- Needed when regulatory standards are strict (e.g., Malaysia).

- Chemical Coagulation & Flocculation: Removes fine colloids

- Membrane Filtration (UF/RO): For ultra-pure discharge or reuse

- Constructed Wetlands: An eco-friendly final polishing step

Emerging Technologies for Sustainable POME Management

As environmental scrutiny grows, mills are adopting advanced treatment systems and circular economy strategies.

Biogas Capture and Utilization:

- Converts waste to renewable energy

- Reduces GHG emissions (methane has a 25x GWP of CO₂)

- Powers mill operations or feeds into national grids

Case Study:

A mill in Sabah, Malaysia, captured biogas to generate 1.5 MW of electricity, offsetting 1,000 tons of CO₂e annually.

Zero Liquid Discharge (ZLD):

A closed-loop system where no POME is released. Steps include:

- Evaporation or membrane treatment

- Solid waste used as fertilizer or biomass fuel

- Drawback: Very high capex and opex

Use case: Large corporate mills pursuing RSPO/ISCC certification

Composting and Bio-Fertilizer Production:

- Solid sludge from POME is rich in nutrients

- Mixed with EFB (empty fruit bunch) to make compost

- Reduces dependency on chemical fertilizers

Algae-Based Treatment Systems:

-

- Algae consume nutrients and CO₂ in POME

- Can be harvested for biodiesel or protein products

- Still in the pilot stage, but it is promising for closed systems

| Treatment Method | Efficiency (BOD Removal) | Capex Estimate | Footprint | Notes |

| Anaerobic Pond | Moderate (70–90%) | $100k–$300k | Large | Biogas generation possible |

| Anaerobic + Biogas | High (90%+) | $500k–$1.2M | Medium | Electricity revenue potential |

| Aerobic + Tertiary | Very High (>95%) | $700k–$2M | Smaller | Higher energy demand |

| Zero Liquid Discharge | Near 100% | $2M–$5M+ | Closed-loop | Expensive, but no effluent |

Cost Considerations for POME Treatment

Initial Investment Estimates:

- Anaerobic pond system (small mill): $100,000–$300,000

- Biogas recovery + genset: $500,000–$1.2 million

- Aerobic + tertiary polishing unit: $700,000–$2 million

- Full ZLD system: $2 million–$5 million+

Operating Costs:

- Electricity, chemicals, labor, and maintenance

- Ranges from $1–5 per m³ of POME

ROI Possibilities:

- Biogas electricity sale or offsetting diesel generators

- Fertilizer sales from treated sludge

- Avoidance of fines and export market access

Best Practices to Ensure Compliance and Efficiency

Regular Monitoring:

- Frequent sampling of effluent for BOD, COD, pH, and TSS

- Online sensors help automate alerts

Operator Training:

- Trained staff can optimize performance and reduce system failure

Preventive Maintenance:

- Routine checks on pumps, blowers, valves, and biogas digesters

Sludge Management:

- Dewatering and composting avoid sludge buildup and reduce odors

Record Keeping:

- Maintain environmental logs for audit and certification purposes

Certifications and Sustainability Compliance

Meeting environmental standards isn’t just about avoiding penalties—it’s a path to market differentiation.

Key Certifications:

- RSPO (Roundtable on Sustainable Palm Oil)

- MSPO / ISPO (Malaysian/Indonesian Sustainable Palm Oil)

- ISCC (International Sustainability and Carbon Certification)

These require documented environmental management systems, regular audits, and verified POME treatment processes.

Benefit:

Certified mills attract more buyers, command better prices, and gain access to EU, US, and Japanese markets.

POME is a formidable challenge—but also a powerful opportunity. With increasing regulatory pressures and market expectations, palm oil mills must go beyond basic compliance. Modern treatment technologies, efficient waste-to-resource strategies, and sustainability frameworks offer clear paths to environmental stewardship and profitability.

By adopting proper POME management systems, companies can:

- Protect local ecosystems and water bodies

- Avoid costly penalties and shutdowns

- Generate value from waste

- Strengthen brand trust and market competitiveness

The road to compliance may require investment, but the returns—in cost savings, environmental impact, and long-term success—are more than worth it.