The production of palm oil has progressed to satisfy worldwide demand while emphasizing sustainability and efficiency. Central to this process is the sterilization tank—the first key unit in fresh fruit bunch (FFB) treatment, impacting oil yield, quality, and mill performance.

Understanding the Purpose of Sterilization Tanks

Sterilization tanks are pressure vessels designed to steam fresh fruit bunches (FFBs) at high temperatures and pressure for a specific period, usually around 140–145°C for 60–90 minutes. The goal is threefold:

Inactivate lipase enzymes in the fruit that cause oil degradation,

Loosen the fruitlets from the bunch stalk for easier stripping.

Soften fruit tissue to facilitate better oil extraction during pressing.

Without effective sterilization, the free fatty acid (FFA) content in crude palm oil (CPO) rises, leading to lower oil quality and economic losses.

The Science Behind Sterilization

Sterilization is primarily a thermal treatment process involving saturated steam. It achieves the following biochemical and physical changes in palm fruit:

| Process Objective | Temperature (°C) | Result |

| Lipase inactivation | > 60°C | Prevents FFA increase |

| Protein denaturation | > 100°C | Softens mesocarp |

| Cell rupture | ~140°C | Aids oil release |

| Fiber loosening | ~140°C | Enhances fruit detachment |

The steam also helps kill microorganisms, making sterilization a semi-hygienic step that contributes to the food-grade safety of palm oil.

Types of Sterilization Tanks in Use

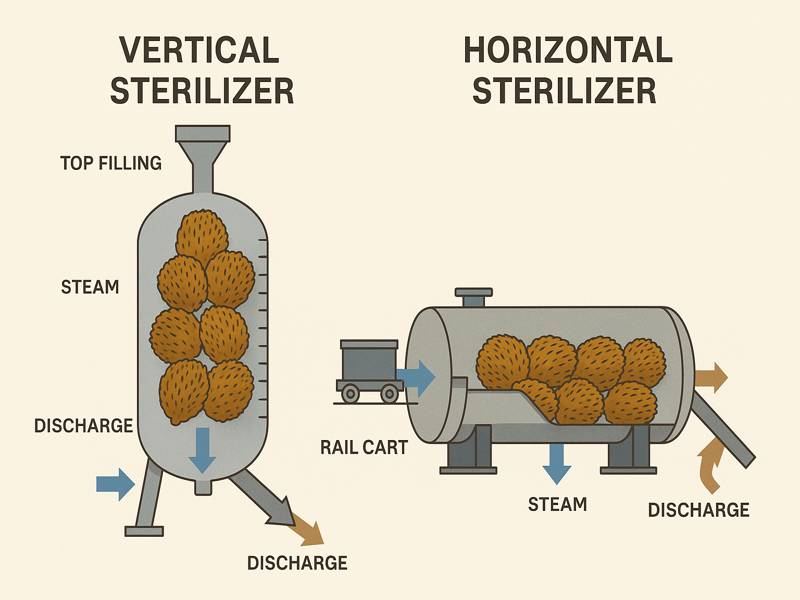

Setting up a palm oil mill generally uses one of the following types of sterilizers:

| Type | Description | Advantages | Common Usage |

| Horizontal Sterilizer | A cylindrical pressure vessel is laid horizontally. Can be single, double, or triple-door. | Robust, easy to clean, large capacity. | Traditional mills with batch processing. |

| Vertical Sterilizer | Cylindrical tank in upright position; FFBs loaded from the top. | Smaller footprint, better energy efficiency. | Newer mills, automated systems. |

| Continuous Sterilizer | Works on a continuous flow principle rather than batches. | High throughput, low labor. | Large, modern mills. |

| Modular Sterilizers | Compact units integrated with mini-mills. | Ideal for mobile or small-scale operations. | Remote or village-scale mills. |

The choice depends on processing capacity, land space, automation level, and investment cost.

Key Components and Features

A modern sterilization tank is more than just a pressure vessel. It includes:

- Steam Inlet/Outlet: Delivers saturated steam and discharges condensate.

- Pressure & Temperature Sensors: Ensures safety and process control.

- Condensate Trap: Prevents water accumulation that may reduce steam efficiency.

- Safety Valves: Prevent explosions from overpressure.

- Cages & Rails: For loading and unloading FFBs.

Automation systems, such as programmable logic controllers (PLCs), are increasingly used to regulate sterilization cycles, improving reproducibility and labor efficiency.

The Working Principle of a Sterilization Tank

A typical sterilization cycle includes:

- Loading: FFBs are loaded into the cage or conveyor, depending on the design.

- Steam Charging: High-pressure steam (usually 3–4 bar) is introduced.

- Holding Phase: The temperature is maintained for 60–90 minutes to complete enzyme inactivation and fruit softening.

- De-pressurization: Steam is vented, and tanks are brought to atmospheric pressure.

- Unloading: Sterilized FFBs are sent to the thresher for fruit separation.

Some advanced systems also include vacuum or dry heating stages to further optimize oil recovery and minimize condensate losses.

How Sterilization Tanks Improve Oil Yield and Quality

Effective sterilization affects both the quantity and quality of crude palm oil (CPO):

- Higher Oil Yield: Properly softened fruits yield more oil during mechanical pressing.

- Reduced FFA Content: Enzyme inactivation minimizes hydrolytic degradation, lowering FFA to <3%.

- Preserved Carotenoids: Efficient tanks prevent overheating, protecting the natural red color of palm oil.

- Lower Contaminants: By killing microbes, sterilizers reduce the risk of mycotoxins or harmful residues.

A poorly designed or maintained sterilization tank can reduce oil yield by up to 5%, significantly impacting profitability.

Design Considerations for Modern Sterilization Tanks

Modern mill operators look for sterilizers that optimize the following:

- Capacity: Ranges from 1.5–3.0 tons per batch in small units to over 30 tons for industrial tanks.

- Steam Consumption: Efficient insulation and optimized steam injection patterns can cut energy usage by up to 15%.

- Cycle Time: Shorter sterilization cycles improve mill throughput.

- Automation: Integration with PLC and SCADA systems enables real-time temperature, pressure, and cycle control.

- Cleaning Access: Tanks must be easy to inspect and clean to prevent the buildup of biomass or contaminants.

Advanced designs now include features like double-walled chambers, self-cleaning surfaces, and automated safety valves.

Energy Optimization in Sterilization Tanks

Sterilizers are among the largest energy consumers in palm oil mills. Key energy-saving strategies include:

| Strategy | Description | Potential Savings |

| Steam Condensate Recovery | Reusing condensate water to generate more steam. | 8–12% |

| Insulated Chambers | Prevents heat loss during the holding phase. | 5–10% |

| Heat Integration | Using heat exchangers to pre-warm incoming FFBs. | 6–9% |

| Intelligent Control | PLC systems adjust steam input based on real-time data. | 5–8% |

Environmental Compliance and Effluent Reduction

Sterilization also impacts waste generation, particularly Palm Oil Mill Effluent (POME):

- Traditional Horizontal Sterilizers produce more condensate, which adds to POME volume.

- Vertical and Continuous Sterilizers produce less condensate due to closed-loop steam systems.

- Advanced Condensate Recovery Systems help reuse water, lowering total effluent volume.

Compliance with national regulations—like those in Malaysia, Indonesia, or Nigeria—often hinges on sterilizer water usage and waste management.

Common Operational Issues and Solutions

| Issue | Cause | Solution |

| Uneven steaming | Poor steam distribution | Upgrade spray headers and check pressure uniformity |

| Fruit overcooking | Excess sterilization time | Calibrate timers and temperature sensors |

| Cage jamming | Misalignment or overload | Use auto-alignment systems and monitor loading |

| Low oil yield | Incomplete enzyme inactivation | Maintain consistent 140–145°C for a minimum of 60 minutes |

| High energy use | Steam leakage or poor insulation | Inspect seals and upgrade insulation |

Case Study: Upgrading from Horizontal Sterilizer to Vertical Sterilizer

We have a customer from East Malaysia, a 45 t/h palm oil mill, who upgraded its three horizontal sterilizers to four vertical autoclaves in 2022. Results after one year:

| Metric | Before (Horizontal) | After (Vertical) | Change |

| Steam Consumption | 750 kg/ton FFB | 580 kg/ton FFB | -22.7% |

| Oil Yield | 19.5% | 20.3% | +0.8% |

| POME Volume | 0.9 m³/ton FFB | 0.65 m³/ton FFB | -27.8% |

| Downtime | 3 hours/week | 1.5 hours/week | -50% |

The investment paid off in 16 months through fuel savings and increased oil recovery.

Integration with Overall Mill Design

In a modern palm oil mill, sterilization tanks are designed as part of a holistic system including:

- FFB Reception and Handling

- Thresher and Pressing Stations

- Kernel Recovery and Oil Clarification

- Effluent Treatment and Energy Recovery

The placement of sterilizers affects material flow, energy pipelines, steam routing, and even building layout. Hence, design engineers consider sterilizers early during the planning phase.

Conclusion

Sterilization tanks have evolved from basic steam chambers to advanced systems that enhance yield, efficiency, safety, and compliance. Modern designs—from batch to continuous—reflect the industry’s move toward sustainability.