As global demand for palm oil grows, understanding its production—from crude milling to refining—is essential. This article explores the key differences, workflows, technologies, and challenges of both stages, offering valuable insights for industry professionals and stakeholders alike.

Overview of the Palm Oil Processing Chain

The palm oil value chain begins with the cultivation of oil palm trees (Elaeis guineensis) and progresses through harvesting, crude oil extraction, refining, and final product formulation. It can be divided into two main sectors:

- Crude palm oil process (Upstream): Focused on extracting unrefined oil from fresh fruit bunches (FFB).

- Refinery Operations (Downstream): Involve purifying and modifying the crude oil into usable consumer or industrial products.

Understanding the distinction between these two sectors is essential for optimizing production efficiency, ensuring quality, and achieving regulatory compliance.

Crude Palm Oil Mill Operations

Purpose and Function

The purpose of a crude palm oil mill is to extract oil from the fruitlets of harvested FFBs as quickly and efficiently as possible to avoid deterioration in oil quality. The focus is on mechanical extraction and moisture removal, resulting in crude palm oil (CPO) and palm kernels.

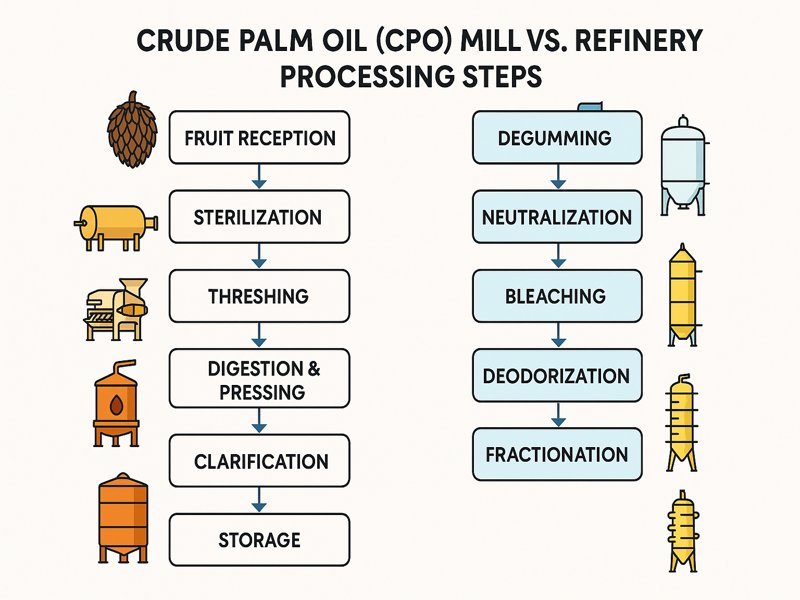

Key Process Steps in the CPO Mill

a) Sterilization

- Fresh fruit bunches are steamed under pressure (usually 3 bar) to soften the fruits and deactivate enzymes that cause oil spoilage.

- Conducted in horizontal or vertical sterilizer tanks.

b) Threshing

A mechanical thresher separates the sterilized fruitlets from the bunch stalks.

c) Digestion

Fruitlets are heated and mashed in digesters using rotating shafts to release the oil from the mesocarp.

d) Pressing

The mashed pulp is pressed, often using a twin-screw press, to extract crude oil.

e) Clarification

The oil-water mixture is settled in large tanks. Crude palm oil is produced after solids and water are eliminated.

f) Kernel Recovery

- The pressed fruit pulp is further processed to extract palm nuts.

- Palm kernels are separated from the shells and used to produce palm kernel oil.

Equipment in a CPO Mill

| Equipment | Function |

| Sterilizer | Steam-treat FFBs to halt enzyme activity |

| Thresher | Remove fruitlets from the bunch |

| Digester | Mash and heat fruitlets |

| Screw Press | Mechanically extract oil |

| Clarification Tank | Settle and separate oil from solids/water |

| Kernel Separator | Recover kernels from fiber and nuts |

Output and By-products

- Main Products: Crude palm oil (CPO), palm kernel oil

- By-products: Palm oil mill effluent (POME), empty fruit bunches (EFB), fibers, shells

These by-products can be reused in composting, biomass energy, or animal feed, increasing sustainability.

Palm Oil Refinery Operations

Purpose and Function

Refinery operations aim to transform crude palm oil into refined, bleached, and deodorized (RBD) palm oil, making it suitable for food products, cosmetics, pharmaceuticals, and industrial applications. This phase involves chemical and physical refining techniques to remove impurities and unwanted compounds.

Key Refining Processes

a) Degumming

Hydrates and removes gums (phospholipids) using water, acid, or enzymatic agents.

b) Neutralization

- Free fatty acids (FFAs) are removed using caustic soda (NaOH).

- This forms soapstock, which is later separated.

c) Bleaching

Bleaching: To get rid of colors and trace metals, the oil is treated with bleaching earth or activated carbon.

d) Deodorization

High-temperature steam (~240°C) under vacuum removes odor and taste components.

e) Fractionation (Optional)

- Divides the oil into two parts: liquid (olein) and solid (stearin).

- Used for customizing the oil for different applications, like margarine or frying oil.

Equipment in a Palm Oil Refinery

| Equipment | Function |

| Degumming Reactor | Hydrate and remove gums |

| Neutralization Vessel | Reduce FFAs through alkali neutralization |

| Bleaching Tower | Absorb color pigments and impurities |

| Deodorizer Column | Remove volatile odor and taste compounds |

| Fractionation Plant | Separate olein and stearin |

| Filtration Unit | Remove residues and filter the final oil |

Output and By-products

- Main Products: RBD palm oil, RBD palm olein, RBD palm stearin

- By-products: Soapstock, spent bleaching earth, distillates (used for tocopherol or fatty acid production)

Key Differences Between CPO Mill and Refinery

| Factor | Crude Palm Oil Mill | Refinery Operation |

| Input | Fresh Fruit Bunches (FFB) | Crude Palm Oil (CPO) |

| Output | Crude Palm Oil and Palm Kernel | Refined Palm Oil, Olein, Stearin |

| Focus | Mechanical Extraction | Chemical and Physical Purification |

| Technology | Boilers, Digesters, Presses | Reactors, Columns, Filtration Systems |

| By-products | POME, EFB, Shells | Soapstock, Distillates, Bleaching Earth Waste |

| Main Use | Industrial raw material | Edible oil, cosmetics, biofuel, oleochemicals |

| Automation Level | Moderate | High |

| Environmental Impact | High organic load in wastewater (POME) | Emissions and chemical waste management are required |

Integration Opportunities

Some companies opt to integrate both mill and refinery operations for greater control and efficiency. Integration offers:

- Improved Traceability: From plantation to final product

- Higher Profit Margins: By selling value-added products

- Better Inventory Control: Raw material security

- Reduced Transport Costs: Especially in remote plantation areas

Companies like Wilmar International, Sime Darby, and Golden Agri-Resources operate integrated facilities to meet global demands efficiently.

Environmental Considerations

Crude Palm Oil Mill Challenges

- POME (Palm Oil Mill Effluent): Contains high organic load; must be treated in anaerobic ponds or biogas recovery systems.

- Solid Waste: EFB and fibers require disposal or reuse.

Refinery Challenges

- Chemical Waste: Disposal of spent bleaching earth and neutralization by-products.

- Steam and Fuel Use: High energy demand for deodorization processes.

Both sectors are under pressure to adopt RSPO, ISCC, and national sustainability standards to minimize environmental footprints and ensure market acceptance.

Economic Analysis

CPO Mill Costs

Capital cost: $2–10 million depending on capacity (5–60 tons/hour)

Operating costs: Labor, fuel, water, maintenance

ROI influenced by:

- Oil Extraction Rate (OER)

- FFB supply consistency

- POME and biomass reuse strategies

Refinery Costs

Capital cost: $3–30 million, depending on capacity and complexity

Operating costs: Utilities, chemicals, labor, packaging

ROI influenced by:

- Refining Losses (2–3%)

- Product diversification (olein, stearin, specialty fats)

- Export capability and regulatory compliance

Applications of Final Products

| Product Type | End-Use Industries |

| RBD Palm Oil | Cooking oil, margarine, baked goods |

| RBD Palm Olein | Frying oil, food processing |

| RBD Palm Stearin | Shortenings, bakery fats, soap, candles |

| Palm Kernel Oil | Cosmetic creams, surfactants, and shampoos |

| Palm Fatty Acids | Lubricants, detergents, biodiesel |

Refined oils command higher prices and meet international food and health standards, allowing broader market access.

Innovation and Automation Trends

In CPO Mills:

- Continuous sterilizers and mechanized thresher systems

- Automated clarification systems

- Biogas recovery from POME

In Refineries:

- Enzymatic degumming

- Advanced bleaching with minimal earth loss

- AI-driven process control for energy efficiency

These innovations aim to enhance oil yield, reduce environmental impact, and lower operational costs.

Crude oil palm and refineries are distinct but vital stages in palm oil production. Mills extract oil from fruit, while refineries purify it for market use. Understanding their differences helps improve efficiency, guide investments, and meet sustainability goals as the industry evolves under growing global demand.