Vertical sterilizers have become the preferred choice for many palm oil mills seeking a compact layout, safer operation, and reduced labor intensity. However, selecting the right capacity isn’t as simple as picking a vessel size from a catalog. It’s a systemic decision that involves yield targets, pulp quality, steam and water infrastructure, building height, automation level, and a balance of downstream equipment.

What Does a Vertical Sterilizer Do, and Why Does Capacity Matter?

A vertical sterilizer palm oil mill is a pressure vessel that cooks fresh fruit bunches (FFB) with saturated steam to inactivate lipase, loosen fruit from bunch stalks, soften mesocarp for digestion, and improve kernel separation later in the process. Capacity matters because sterilization is typically the pacing step of the front end: under-sized capacity creates upstream congestion and downstream starvation; over-sized capacity locks capital and steam capacity into idle time, increasing cost per ton.

In most mills, vertical sterilizers are operated in batch mode with cages or baskets lifted and lowered via hoist. Each cycle comprises: loading, pre-venting/air removal, pressurization to setpoint, cooking (holding), pressure release, condensate discharge, and unloading. The cycle time sets the relationship between vessel size and hourly throughput.

How Do You Translate Hourly Throughput Into Sterilizer Capacity?

Start with three variables:

- Target throughput (QFFB): tons of FFB per hour (t/h).

- Sterilization cycle time (tcycle): hours per batch per vessel (including all steps).

- Charge per batch per vessel (Cb): net FFB per batch (tons).

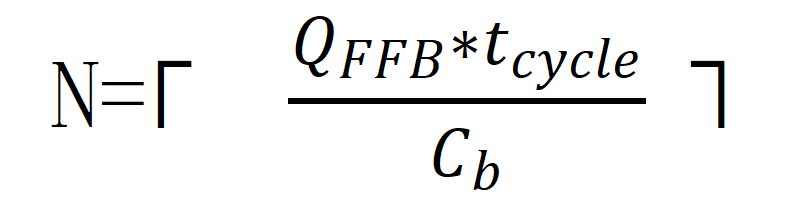

The number of vessels required (N) is:

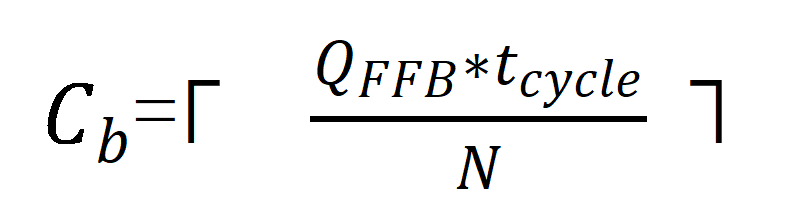

You can back-solve for Cb (vessel size) if you want to fix N for layout reasons:

Typical engineering assumptions

- Cycle time (tcycle): 60–90 minutes (1.0–1.5 h), depending on fruit moisture, pressure ramp profile, venting efficiency, and automation.

- Steam pressure/temperature: 2.8–3.2 bar(g) saturated (≈133–138 °C). Some mills operate up to ≈3.5 bar(g) for particularly tough fruit.

- Cage payload: commonly 2.5–3.5 t FFB per cage. Vertical vessels often take 2–4 cages per batch, depending on shell diameter/height.

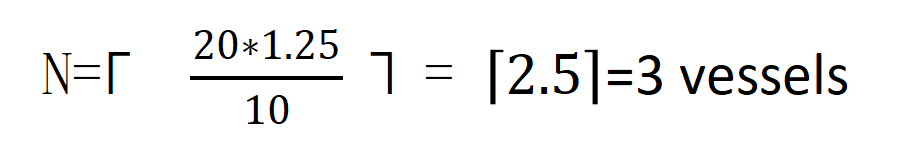

Worked example

- Throughput goal: 20 t/h FFB

- Cycle time: 75 min = 1.25 h

- Candidate batch size: 10 t FFB per vessel

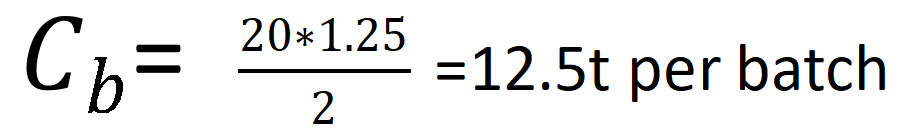

If your building can only accommodate two sterilizer shells, you must increase Cb:

That implies a larger diameter/height or more cages per vessel, plus stronger lifting/hoisting gear and slightly higher steam valve capacity.

What Cycle Time Should You Design For?

Shorter cycles increase hourly output per vessel but demand excellent air removal, dependable steam supply, precise pressure/temperature control, and quick handling at loading/unloading. Use realistic figures from your operations and fruit conditions. As a planning baseline:

- 60 min (aggressive): Requires reliable condensate/air venting, high-automation valves, and consistent fruit. Great for well-run mills with steady steam.

- 75 min (balanced): Commonly achievable with integrated controls and disciplined loading/unloading routines.

- 90 min (conservative): Suitable where steam fluctuation or fruit variability is expected; capacity must be increased to hit the same throughput.

How Does Fruit Quality Affect Capacity Choice?

FFB characteristics directly influence cycle time and effective batch size:

- Ripeness & variety: Under-ripe or denser bunches may need longer holding times to achieve complete inactivation and fruit loosening.

- Moisture content: Higher moisture improves heat transfer but can increase condensate volume; ensure traps and drains are sized accordingly.

- Bunch size distribution: Larger average bunches pack differently in cages; you may need wider cages or reduced fill to maintain steam penetration.

If your supply base spans multiple estates with variable ripeness, select a capacity that meets your worst-case sterilization time without chronically over-cooking best-case fruit. Many mills add a third vessel to operate two at high load while keeping one as a swing/standby to smooth variability.

How Should You Balance Sterilizers With the Rest of the Line?

Sterilizers feed digesters/presses; a mismatch creates losses:

- Digesters/Presses: Confirm that the combined discharge rate from all sterilizers equals or slightly exceeds the digester/press rated throughput. Consider a staggered cycle start (e.g., 10–15 min offsets) so discharge is even.

- Threshing: Ensure the bunch conveyor/stripper can handle the short bursts of discharge without jams. A buffer conveyor with variable speed helps.

- Kernel recovery: Over-sterilization can harden nuts and raise kernel losses; under-sterilization leaves fruit tight on stalks. Capacity should allow correct holding time—not force rushed or extended cycles.

What Are the Utility and Infrastructure Implications?

Steam is the lifeblood of sterilization. Estimate steam demand per ton FFB to check your boiler capacity and piping sizes.

- Steam consumption: 0.30–0.60 t steam/t FFB is typical for vertical systems (including losses). Efficient venting, good insulation, and condensate recovery move you toward the lower end.

- Condensate management: Provide adequately sized steam traps, flash tanks (if recovering), and hot-well return. Poor condensate handling lengthens cycles and wastes energy.

- Water: Expect additional water for make-up and softening (boiler feed), plus washdown. Plan for 1–3 m³/h ancillary demand depending on plant size.

- Power: Hoists, cage transfer, actuated valves, and controls draw modest electrical loads; check hoist motor sizing if increasing Cb or cage count.

Quick utility check table (indicative)

| Target FFB (t/h) | Typical Batch Size Cb (t) | Vessels (N) @ 75 min | Steam Demand (t/h)* | Condensate Return (t/h) |

| 10 | 8–10 | 2 | 3.0–6.0 | 2.4–5.0 |

| 20 | 10–12.5 | 2–3 | 6.0–12.0 | 4.8–10.0 |

| 30 | 12–15 | 3–4 | 9.0–18.0 | 7.2–15.0 |

| 45 | 15–20 | 4–6 | 13.5–27.0 | 10.8–22.5 |

*Assumes 0.30–0.60 t steam per ton FFB. Use your site’s energy audit for final numbers.

What About Footprint, Height, and Building Constraints?

Vertical sterilizers save floor area but require headroom for the shell and hoist. Key points:

- Height: Allow vessel height + freeboard + hoist beam + maintenance clearance. It’s common to require 12–18 m clear height for larger units.

- Hoist capacity: Must exceed the total suspended mass (loaded cage(s) + spreader + slings), with a safety factor. If you increase Cb, verify hoist and supporting structure upgrades.

- Floor loading: Concentrated loads beneath the shell and hoist columns may need localized foundations and tie-beams.

Should You Choose Fewer, Larger Vessels or More, Smaller Ones?

There’s a classic trade-off:

Fewer, larger vessels

- Pros: Lower shell count, fewer valves/instruments, simpler piping; potentially lower CAPEX per ton.

- Cons: Bigger hoist, higher building height, larger surge on downstream equipment at discharge, lower redundancy (one vessel outage = larger capacity loss).

More, smaller vessels

- Pros: Better redundancy and ability to stagger batches for steady discharge; easier maintenance during operation; shorter hoist lifts.

- Cons: More instruments and valves; higher control complexity; potentially higher CAPEX and OPEX for additional auxiliaries.

Many mills find a 3-vessel configuration (medium batch size) strikes a good balance for 15–30 t/h lines, enabling one vessel in cook, one in load/unload, and one in pressurization/venting at any time.

How Do Automation and Controls Influence Capacity?

Automation shortens non-productive time and stabilizes cycle time:

- Automated venting & steam admission: Quickly removes non-condensables; reduces time to temperature.

- Recipe control: Pressure ramp, soak time, and blow-down steps can be stored and reproduced for different fruit conditions.

- Interlocks: Prevent loading under pressure and ensure doors/clamps are properly secured; improves safety and reduces unexpected delays.

- Data logging: Cycle time dispersion analysis helps identify bottlenecks (e.g., slow hoist travel, blocked traps) and supports continuous improvement.

If you’re debating between two capacities, investing in better controls can effectively “add capacity” by cutting minutes from each cycle without increasing vessel size.

What Safety and Compliance Factors Affect Sizing?

Larger vessels mean thicker shells (greater material cost) and more stringent code requirements.

- Design code: Adherence to accepted norms (e.g., ASME Section VIII or equivalent local code).

- Relief capacity: Relief valves sized for worst-case heat input and blocked outlet scenarios.

- Inspection & access: Manways, ladder/cage access, platforms, and clearances for periodic internal inspection.

- Door systems: Hydraulic or mechanical clamps rated for design pressure with interlocks; consider double-door systems for faster changeover if layout allows.

A Step-by-Step Method to Select Capacity

- Fix your throughput target (QFFB) with seasonal peak in mind (e.g., design for 110–120% of average).

- Establish a realistic cycle time (tcycle) from trials or peer benchmarks (e.g., 75 min).

- Choose vessel count (N) guided by redundancy, building height, and downstream buffering.

- Compute required batch size (Cb) and check mechanical feasibility: shell diameter/height, cage count, hoist capacity.

- Verify utilities: boiler steam margin, piping sizes, condensate return, feedwater treatment, and electrical loads.

- Check building/hoist constraints: height, columns, crane girder, foundation.

- Validate line balance: thresher, conveyors, digesters, and presses can accept staggered discharge.

- Simulate or time-study: run a simple Gantt (load/vent/pressurize/hold/blow-down/unload) to verify that staggered batches meet hourly targets.

- Add a contingency factor: 10–15% capacity buffer for fruit variability and planned maintenance.

- Optimize via automation: invest in valves/controls that reduce non-productive minutes and stabilize cycles.

What About Energy Efficiency and OPEX?

Capacity choice affects your energy profile:

- Right-sized vessels minimize dead volume and shell radiation per ton.

- Short, repeatable cycles reduce start-stop transients that waste steam.

- Insulation & trap maintenance often delivers double-digit percentage steam savings.

- Condensate recovery (85–95%) cuts fuel and water costs—size flash tanks and return lines accordingly.

- Heat integration: Some mills pre-heat wash water or feedwater with sterilizer condensate. Factor these benefits into your utility balance when comparing capacities.

Selecting the “right capacity” vertical sterilizer is about system balance, not just vessel volume. Use the sizing equations to translate hourly throughput and cycle assumptions into a concrete combination of number of vessels (N) and batch size (Cb).