Crude palm oil (CPO) is an essential raw material for food and non-food industries worldwide. However, it contains various impurities, among which free fatty acids (FFA) significantly affect its quality, stability, and market value. Efficient removal of FFA is crucial in refining crude palm oil to meet edible oil standards and technical requirements in oleochemical industries.

This article explores the best practices for FFA removal in CPO, from process selection and optimization to emerging technologies and sustainability considerations.

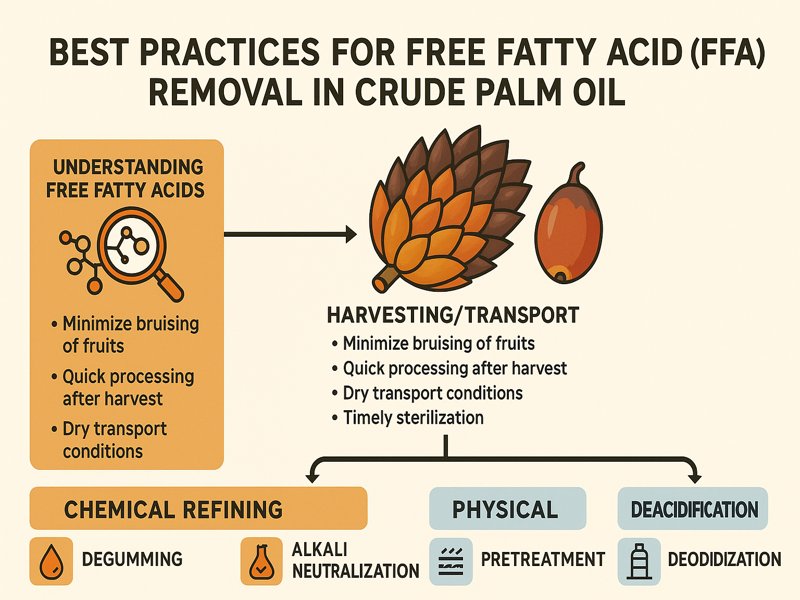

Understanding Free Fatty Acids in Crude Palm Oil

The free fatty acids in palm oil are the result of the hydrolytic breakdown of triglycerides, which mainly occurs during the processing of the palm oil. Lipases released when the palm fruit is damaged catalyze this process, causing the free fatty acid (FFA) content to increase over time.

Key characteristics of FFA in CPO:

- Chemical nature: Primarily palmitic acid, with lesser amounts of oleic and linoleic acids.

- Impact on quality: High FFA leads to unpleasant odor, taste, lower smoke point, and instability.

- Industry standards: Most edible palm oils require FFA content below 0.1–0.5%.

Classification of FFA Removal Techniques

FFA removal in palm oil refining can be broadly classified into two methods:

Physical Refining (Steam Deacidification)

Involves distillation of FFA at high temperature under vacuum using direct steam. FFA is vaporized and condensed separately.

Best for: CPO with low impurities and stable color

Advantages:

- High oil recovery

- Lower chemical usage

- Suitable for large-scale operations

Challenges:

- Requires effective degumming and bleaching beforehand

- Energy intensive

Chemical Refining (Alkali Neutralization)

Involves reacting FFA with caustic soda (NaOH) to form soapstock, which is then separated.

Best for: CPO with high FFA and impurities

Advantages:

- Effective for oil with >5% FFA

- Flexible process control

Challenges:

- Generates soapstock waste

- Higher refining losses

Critical Control Points for FFA Reduction

To achieve optimal FFA removal, several control points must be carefully managed:

Harvesting and Transport

- Minimize bruising: Use gentler harvesting tools to avoid damaging fruits.

- Quick processing: Reduce the delay between harvesting and sterilization to prevent lipase activity.

- Dry transport conditions: Avoid water contact to prevent hydrolysis.

Sterilization

- Timely sterilization: Within 24 hours of harvest to deactivate lipase enzymes.

- Controlled temperature: 130–140°C for 90 minutes is ideal.

Clarification and Storage

- Efficient separation: Remove sludge and moisture quickly post-pressing.

- Inert atmosphere storage: To avoid hydrolysis and oxidation.

Best Practices in Chemical Refining for FFA Removal

Step 1: Degumming

- Remove phospholipids using water, acid, or enzymatic degumming.

- Prevent emulsification during neutralization.

Step 2: Alkali Neutralization

- Add calculated caustic soda (based on FFA titration) to neutralize acids.

- Use controlled agitation and temperature (60–80°C).

Optimization tips:

-

- Slight excess alkali improves FFA removal but increases losses.

- Monitor saponification and pH carefully.

Step 3: Soapstock Separation

- Use centrifuge separators for clean phase separation.

- Recycle soapstock for by-products like acid oil or soap.

Step 4: Washing and Drying

- Multiple hot water washes reduce residual soap and FFA.

- Vacuum drying removes moisture to prevent hydrolysis during storage.

Best Practices in Physical Refining for FFA Removal

Step 1: Pretreatment – Degumming and Bleaching

- Remove phospholipids, metals, and color pigments.

- Use activated clay and silica to adsorb impurities.

Step 2: Deacidification via Steam Distillation

- High vacuum (2–4 mmHg)

- Temperature 240–270°C

- Direct steam injection for 30–60 minutes

Design considerations:

- Structured packing in a column improves vapor-liquid contact.

- Steam spargers ensure uniform stripping.

Step 3: Deodorization (Optional)

-

- Removes residual odor and taste-causing compounds.

- Uses similar conditions as deacidification with longer retention.

Enzymatic and Membrane-Based Alternatives

With growing demand for eco-friendly processes, enzymatic and membrane-based methods offer alternatives to conventional refining.

A. Enzymatic Esterification

- Converts FFA into esters using enzymes and alcohol (like methanol).

- Operates at mild temperature (50–70°C).

- Suitable for high FFA crude oils.

Pros:

- Less oil loss

- Lower temperature, energy saving

- Generates value-added esters

Cons:

- Enzyme cost

- Slower reaction time

B. Membrane Separation

- Ultrafiltration or nanofiltration to selectively separate FFA from triglycerides.

- Still under development for commercial use.

Challenges:

- Membrane fouling

- High initial cost

Process Optimization Strategies

a. FFA Monitoring and Feedback Control

- Online FFA analyzers for real-time monitoring.

- Automated dosing of alkali or steam based on FFA levels

b. Energy Integration

- Recover waste heat from deodorizers and heat exchangers.

- Use multi-effect evaporators to reduce steam consumption.

c. Waste Management

- Recycle soapstock into acid oil.

- Treat condensate water to recover oil traces.

Equipment Best Practices

For Chemical Refining:

- Use high-speed centrifugal separators for soap removal.

- Employ static mixers for better caustic distribution.

- Use acid-resistant materials to prevent corrosion.

For Physical Refining:

- Vacuum systems must be tight to prevent air ingress.

- Use high-efficiency steam ejectors or vacuum pumps.

- Ensure insulation to minimize heat loss.

Comparing the Effectiveness of Different FFA Removal Methods

| Method | FFA Removal Efficiency | Oil Loss | Chemical Use | Energy Requirement | Suitability |

| Chemical Neutralization | High (>95%) | Moderate | High (NaOH) | Medium | High FFA CPO |

| Physical Refining | High (90–98%) | Low | Low | High | Low FFA CPO |

| Enzymatic Esterification | Moderate (85–90%) | Low | Low | Low | High FFA CPO |

| Membrane Separation | Emerging | Low | None | Medium | R&D stage |

Sustainability and Regulatory Considerations

Environmental Compliance

- Ensure effluent from refining plants meets discharge standards.

- Install effluent treatment plants (ETPs) for soapstock and wash water.

Food Safety Standards

- FFA removal must not introduce harmful residues.

- Follow Codex and national edible oil standards (e.g., <0.1–0.5% FFA).

Carbon Footprint Reduction

- Adopt energy-efficient distillation and heat integration.

- Consider carbon-neutral refining via biogas from POME.

Common Mistakes to Avoid in FFA Removal

Overdosing on caustic soda leads to excess soap formation and oil loss.

- Poor degumming before physical refining: Causes emulsification and poor FFA vaporization.

- Inadequate vacuum system maintenance reduces FFA stripping efficiency.

- Neglecting feedstock quality: High moisture or impurities raise refining costs.

- Ignoring soapstock valorization: Wastes potential by-products and increases cost.

Free fatty acid removal is a vital step in refining crude palm oil, directly impacting product quality, yield, and profitability. Whether using chemical or physical refining methods, best practices—such as optimized caustic dosing, efficient vacuum systems, and proper pretreatment—can significantly improve refining efficiency and sustainability.

Emerging technologies like enzymatic processes and membrane separation may offer eco-friendly alternatives, but traditional methods remain dominant due to proven scalability and cost-effectiveness. The ultimate choice of method depends on CPO quality, refinery size, energy availability, and market requirements.