Cameroon is one of Central Africa’s most promising agricultural hubs, with vast fertile land, abundant rainfall, and a long history of palm cultivation. As global and domestic demand for palm oil continues to grow—for use in food, cosmetics, industrial products, and biofuels—many entrepreneurs are looking to invest in palm oil processing plants to tap into this profitable sector.

If you’re considering entering the palm oil industry in Cameroon, this article provides a comprehensive, step-by-step guide covering everything from feasibility studies and land acquisition to plant setup, equipment selection, regulatory requirements, and operational strategies. By the end, you’ll have a clear roadmap for launching a successful palm oil processing business.

Understanding the Palm Oil Industry in Cameroon

Market Overview

Cameroon is the third-largest palm oil producer in Africa, after Nigeria and Côte d’Ivoire. The country produces over 300,000 metric tons of crude palm oil annually, with both industrial plantations (e.g., SOCAPALM, PAMOL) and smallholder farmers contributing to the sector. Domestic demand is high—especially for edible oil, soap manufacturing, and cosmetics—while exports to neighboring Central African countries are increasing.

However, Cameroon still imports palm oil to meet total consumption needs, creating a market gap for new entrants. With supportive government policies, rising local demand, and proximity to regional markets, palm oil processing presents significant investment potential.

Climatic & Agronomic Advantage

Palm oil thrives in humid tropical climates with well-distributed rainfall and temperatures between 24 °C and 32 °C. Cameroon’s coastal and forest regions—such as Littoral, Southwest, South, and Center—provide ideal growing conditions for oil palms, ensuring a steady fresh fruit bunch (FFB) supply for processing plants.

Key Opportunities

- Processing fruit from smallholder farmers who lack modern mills

- Supplying local edible oil refiners and soap manufacturers

- Exporting to landlocked Central African countries

- Developing value-added products such as refined oil, palm kernel oil, and biomass energy

Conducting a Feasibility Study

Before you start construction or buy equipment, a well-structured feasibility study is essential to assess technical, financial, and market viability.

Market Analysis

- Demand estimation: Calculate domestic consumption volumes in your target area.

- Competitor mapping: Identify existing mills, capacities, and market shares.

- Price trends: Study local crude palm oil (CPO) and refined oil prices to estimate revenue potential.

- Buyer identification: Secure letters of intent from wholesalers, refiners, or industrial users.

Raw Material Assessment

- Evaluate the availability of FFB within a 30–50 km radius (to minimize transportation costs).

- Survey local farmers, cooperatives, and plantations.

- Consider backward integration by developing your own nucleus estate for guaranteed supply.

Technical & Financial Viability

- Determine plant capacity: Small (1–5 TPH), medium (5–20 TPH), or large (20+ TPH).

- Estimate capital expenditure (land, construction, machinery, utilities).

- Project operational costs (labor, maintenance, transport, utilities).

- Prepare cash flow forecasts and return-on-investment models.

- Analyze risk factors: seasonality, price fluctuations, logistics, and regulations.

A professional feasibility report will also be required for bank loans or investment partnerships.

Acquiring Land and Securing Raw Materials

Land Acquisition

Choose land close to palm plantations to reduce FFB transport time (ideally <2 hours from harvest to processing). The site should:

- Be accessible by road for truck delivery and product distribution

- Have sufficient space for expansion (minimum 1–3 ha for small plants)

- Provide a reliable water and electricity supply, or room for generators and water tanks

- Meet zoning and environmental regulations

In Cameroon, land can be acquired through purchase, lease, or partnership with cooperatives or communities. Ensure proper legal documentation and title registration.

Raw Material Supply Agreements

Secure long-term FFB supply contracts with local smallholders, cooperatives, or plantations. Many entrepreneurs combine:

- Outgrower schemes: providing seedlings and inputs to farmers in exchange for a guaranteed fruit supply

- Own nucleus estates: cultivating their own oil palms for base supply

- Open market buying: sourcing extra FFB during peak harvest seasons

Reliable raw material supply is critical for consistent mill operation and profitability.

Choosing the Right Processing Capacity and Technology

Palm oil processing plants vary by scale and automation level, each with different investment and operational requirements.

| Plant Type | Capacity (TPH) | Description | Typical Users |

| Small/Artisanal | 0.5–5 | Simple manual or semi-mechanical presses, low cost | Cooperatives, village processors |

| Medium-Scale | 5–20 | Mechanical presses, modern sterilizers, and better efficiency | Entrepreneurs, SMEs, farmer groups |

| Large-Scale Industrial | 20+ | Full automatic lines, sterilization digesters, clarification systems | Corporate plantations, export producers |

For most private investors in Cameroon, medium-scale plants (5–10 TPH) offer a balanced entry point—affordable investment, good processing efficiency, and manageable operations.

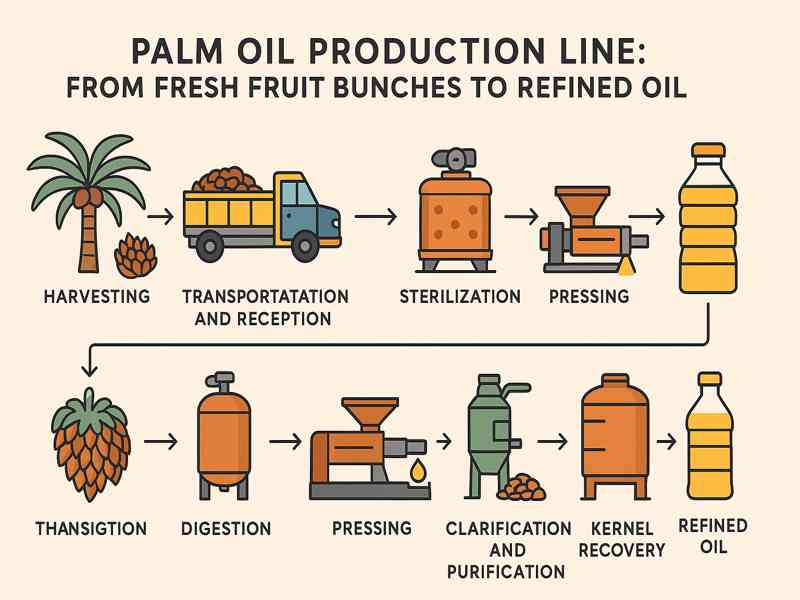

List Of Palm Oil Processing Equipment:

- FFB reception and weighing system

- Sterilizer (steam or hot water) to soften fruits

- Threshing machine to separate fruit from bunches

- Digesting and pressing unit (screw press)

- Clarification and purification tank

- Oil storage tanks

- Boiler and sterilization system

- Kernel recovery system (optional for value addition)

Invest in reliable, easy-to-maintain machinery with local technical support. China, Malaysia, and Nigeria supply most of the affordable equipment for African palm oil processors.

Designing and Constructing the Plant

Plant Layout

An efficient layout should minimize FFB handling time and optimize material flow. The layout usually includes:

- Reception & Sterilization Area

- Threshing & Digestion Section

- Pressing & Clarification Area

- Kernel Recovery Section

- Boiler House & Workshop

- Storage Tanks & Dispatch Section

- Administrative Block & Laboratory

Construction Considerations

- Use reinforced concrete floors for heavy machinery

- Provide drainage and effluent management systems to handle palm oil mill effluent (POME)

- Ensure ventilation and safety measures in boiler and press areas

- Allow space for future capacity expansion

Hiring a local civil engineer familiar with agro-industrial construction will reduce delays and compliance issues.

Regulatory Approvals and Business Formalities

Starting a palm oil processing business in Cameroon requires legal registration and regulatory approvals.

Registration of the Company

- Join the Centre de Formalités de Création d’Entreprises (CFCE) by registering.

- Obtain a Tax Identification Number (TIN).

- Apply for relevant business permits depending on company structure (Société Anonyme, SARL, etc.).

Permits for operations and the environment

- As mandated by the Environment Ministry, carry out an Environmental Impact Assessment (EIA).

- Obtain land use approval and construction permits from local authorities.

- This eliminates the requirement for chemical processes that create trans fats.

- Comply with local labor laws, fire safety standards, and environmental regulations.

Financing and Incentives

Cameroon’s government and development banks sometimes offer agricultural credit lines, tax incentives, or investment promotion benefits under programs like:

- Cameroon Investment Promotion Agency (CIPA) incentives

- AFDB and local banks’ agro-industry financing

- Partnerships with farmer cooperatives for shared ownership models

Hiring and Training Labor

Palm oil processing requires a mix of skilled and semi-skilled labor, including:

- Plant manager/operations supervisor

- Boiler and mechanical technicians

- Press and clarification operators

- Quality control and laboratory personnel

- Weighbridge clerk and logistics workers

- General labor for fruit handling and cleaning

Investing in training programs—either through equipment suppliers or local agricultural institutes—improves productivity, reduces breakdowns, and ensures compliance with hygiene and safety standards.

Ensuring Product Quality and Standards

To compete in local and export markets, your palm oil must meet national and international quality specifications.

Key Quality Parameters

- Free Fatty Acid (FFA) Content: Should be <5% for crude palm oil.

- Moisture and Impurities: Should be <0.25% for commercial grades.

- Color and odor: Should be consistent, without burnt or fermented smell.

Quality Control Systems

- Install basic laboratory equipment to measure FFA, moisture, and impurities.

- Implement Good Manufacturing Practices (GMP).

- Maintain traceability from FFB reception to oil dispatch.

- Consider certification for ISO 22000, HACCP, or RSPO if targeting premium markets.

Marketing and Distribution

Once production begins, establishing reliable sales and distribution channels ensures cash flow and business growth.

Target Markets

- Local wholesalers and retailers in urban centers

- Edible oil refiners who buy crude palm oil for further processing

- Soap and cosmetics manufacturers

- Export markets in Chad, the Central African Republic, or Gabon

Branding and Packaging

For retail markets, consider branding, bottling, and labeling your palm oil to capture added value. Transparent PET bottles in 1L, 5L, and 20L sizes are popular formats.

Transportation and Logistics

Arrange bulk tankers or trucks for large buyers and smaller delivery vehicles for regional markets. Proper storage (away from sunlight and moisture) preserves oil quality during distribution.

Managing Sustainability and Waste

Modern palm oil plants must address environmental and social responsibilities.

Waste Management

Palm Oil Mill Effluent (POME) must be treated using settling ponds, anaerobic lagoons, or biogas digesters to prevent water pollution.

Empty fruit bunches (EFB) can be composted or used as biomass fuel.

Palm kernel shells can serve as boiler fuel or be sold as an energy source.

Community Engagement

Engage local communities early to secure social license to operate. Create outgrower partnerships, provide employment, and support infrastructure development. This builds long-term goodwill and supply reliability.

Financial Considerations and Profitability

Investment Cost Estimate (Medium Plant: 5–10 TPH)

| Item | Estimated Cost (USD) |

| Land & Site Development | 50,000–100,000 |

| Construction & Civil Works | 150,000–300,000 |

| Machinery & Installation | 300,000–600,000 |

| Utilities (boilers, gensets, tanks) | 100,000–200,000 |

| Working Capital | 50,000–100,000 |

| Total | 650,000–1.3M |

Operating Costs

- FFB procurement: 60–70% of total cost

- Labor and maintenance

- Energy and water

- Packaging and transportation

Revenue Streams

- Sale of crude palm oil (main product)

- Palm kernel oil and cake (by-products)

- Biomass energy (optional)

Profit margins depend on FFB cost vs. CPO selling price and plant utilization rate. Medium plants can often achieve 15–25% gross profit margins if well managed.

Starting a palm oil processing plant in Cameroon is a strategic agribusiness opportunity backed by strong domestic demand, favorable growing conditions, and regional market access. However, success depends on careful planning, reliable raw material supply, efficient technology, regulatory compliance, and quality control.

By following these key steps:

- Conduct a detailed feasibility study

- Secure land and FFB supply contracts

- Choose an appropriate plant capacity and technology

- Obtain all legal and environmental approvals

- Construct a well-designed plant and hire skilled staff

- Ensure quality assurance and effective marketing

Entrepreneurs can build profitable, sustainable palm oil processing ventures that contribute to local development and capture growing market opportunities in Cameroon and beyond.