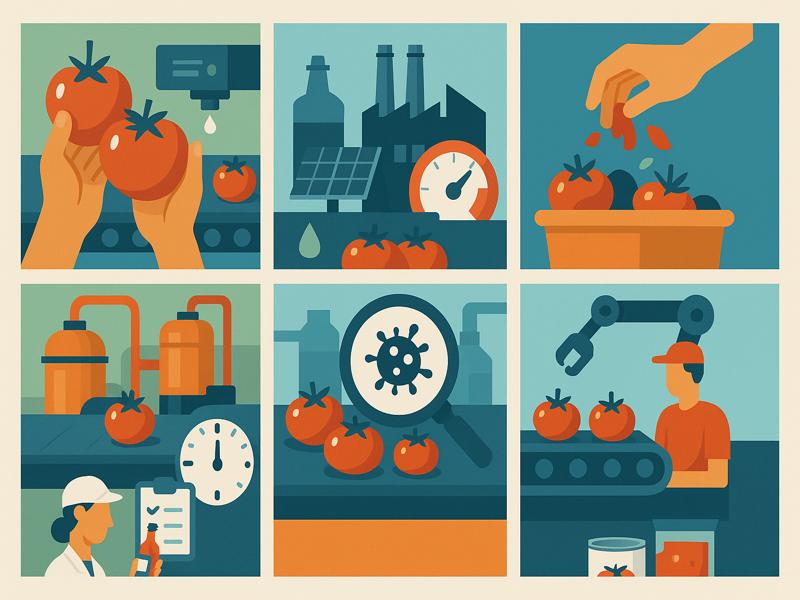

Tomato processing plants play a crucial role in transforming fresh tomatoes into products like paste, puree, ketchup, juice, and canned goods. However, running a tomato processing operation isn’t without its challenges. From raw material inconsistencies to regulatory compliance, plants face multiple hurdles that can affect efficiency, product quality, and profitability.

Variability in Tomato Quality and Supply

The Challenge:

Tomatoes are highly perishable and subject to variability in size, ripeness, acidity, and sugar content, depending on the region, season, and farming practices. Inconsistent raw material quality can impact yield, taste, and processing efficiency.

Solution:

- Establish long-term contracts with farmers and co-ops to ensure a consistent supply.

- Introduce quality-based procurement systems.

- Sort tomatoes according to size, color, and ripeness using sensors and AI-powered grading devices.

- Invest in ripening rooms or controlled-atmosphere storage for better uniformity before processing.

High Water and Energy Consumption

The Challenge:

Tomato processing requires large volumes of water for washing, peeling, and concentrating. It also involves significant energy use for heating, evaporation, and sterilization. These inputs have an adverse effect on the environment and raise operating costs.

Solution:

- Install water recycling and filtration systems to reuse water.

- Adopt energy-efficient boilers, evaporators, and heat recovery systems.

- Use solar panels or biomass boilers to supplement traditional energy sources.

- Monitor utility usage with IoT-enabled sensors for real-time optimization.

Waste Management and By-Product Utilization

The Challenge:

Tomato skins, seeds, and other residues account for a significant portion of production waste. Improper disposal can attract pests, create odor problems, and violate environmental regulations.

Solution:

- Convert waste into animal feed, compost, or biogas through anaerobic digestion.

- Extract valuable compounds like lycopene, fiber, and oil from tomato waste.

- Partner with third-party recyclers or invest in waste valorization technology.

Short Harvest and Processing Window

The Challenge:

The tomato harvest season is limited to a few months. Plants must operate at peak capacity during this period, often leading to labor shortages, equipment breakdowns, and bottlenecks.

Solution:

- Schedule preventive maintenance before the harvest begins.

- Train seasonal labor in advance and develop a temporary staffing pool.

- Use automation to reduce dependency on manual tasks.

- Store semi-processed tomato pulp/paste aseptically to extend production into the off-season.

Microbial Contamination and Food Safety Risks

The Challenge:

Tomatoes are susceptible to microbial contamination during handling, especially in hot and humid environments. Contaminated batches can lead to spoilage, recalls, or foodborne illnesses.

Solution:

- Follow HACCP (Hazard Analysis and Critical Control Points) protocols.

- Use hygienic design in all equipment and processing areas.

- Sanitize surfaces and conveyors regularly with food-safe chemicals.

- Implement rapid microbial testing methods like ATP bioluminescence or PCR.

Labor Shortages and Workforce Management

The Challenge:

Finding and retaining skilled labor for processing plants is increasingly difficult. Seasonal spikes in demand further complicate workforce planning and employee retention.

Solution:

- Offer incentives, housing, or transportation to attract seasonal workers.

- Cross-train staff to handle multiple roles.

- Use robotic systems for repetitive tasks like sorting and packaging.

- Implement HR software for scheduling, performance tracking, and payroll automation.

Compliance with Food Safety and Environmental Regulations

The Challenge:

Tomato processors must comply with national and international standards like the FDA, FSSAI, ISO 22000, and environmental norms. Penalties or plant closures may result from noncompliance.

Solution:

- Hire a dedicated compliance officer or food safety consultant.

- Digitize documentation for traceability and audit readiness.

- Regularly train employees on GMP (Good Manufacturing Practices) and regulatory changes.

- Use ERP systems that integrate traceability, inventory, and QA monitoring.

Packaging and Shelf Life Optimization

The Challenge:

Tomato products are sensitive to oxidation, moisture, and microbial spoilage. Choosing the wrong packaging can shorten shelf life and increase returns or customer complaints.

Solution:

- Make use of vacuum or aseptic packaging methods.

- Choose multi-layer coatings that are moisture and oxygen-resistant.

- To replicate real-world circumstances, do accelerated shelf-life testing.

- Label products with storage guidelines and use-by dates clearly.

Equipment Downtime and Maintenance Issues

The Challenge:

Breakdowns in key machines like pulpers, evaporators, or sterilizers during peak season can halt operations and cause costly delays.

Solution:

- Implement a predictive maintenance system using sensors and analytics.

- Keep critical spares in inventory during the peak season.

- Schedule minor repairs and cleaning during shift changes or overnight.

- Provide in-house technician training to reduce reliance on third-party service providers.

Price Volatility and Market Competition

The Challenge:

Fluctuating prices for fresh tomatoes and increasing competition from both domestic and international processors make it hard to maintain profitability.

Solution:

- Diversify the product portfolio to include high-margin products like organic ketchup or tomato extract.

- Lock in prices through futures contracts or supplier agreements.

- Optimize production costs using lean manufacturing principles.

Summary Table: Top Challenges and Solutions

| Challenge | Description | Key Solution |

| Variability in Tomato Quality | Inconsistent ripeness, size, acidity | Source contracts, sorting tech |

| High Water/Energy Usage | Increased operational costs | Recycling systems, energy-efficient equipment |

| Waste Management | Accumulated tomato waste | By-product recovery, composting |

| Short Harvest Window | Seasonal bottlenecks | Pre-season prep, off-season processing |

| Food Safety Risks | Contamination, spoilage | HACCP, sanitation, testing |

| Labor Shortage | Difficult to hire seasonal workers | Automation, incentives, cross-training |

| Regulatory Compliance | Complex food/environment rules | Training, digitized records |

| Packaging Challenges | Shelf-life reduction | Barrier packaging, aseptic methods |

| Equipment Downtime | Production halts | Predictive maintenance, trained technicians |

| Market Volatility | Price swings, competition | Diversification, cost reduction |

Tomato processing plants face a unique set of operational, logistical, and regulatory challenges, especially given the perishable nature of raw materials and the seasonal nature of production. However, these challenges can be effectively managed through a combination of technology, planning, and continuous improvement practices.

If you are planning to invest in or upgrade a tomato processing plant, feel free to contact us with any questions to ensure long-term success.