One of the most widely used edible oils worldwide is palm oil, which is made from the fruit of the oil palm tree. Behind this essential product is a complex, well-engineered process powered by specialized machinery. In order to convert fresh fruit bunches (FFB) into premium crude palm oil (CPO), each machine is essential.

Estación de recepción de materias primas

Purpose:

The palm oil production process begins with the reception of freshly harvested fruit bunches. This station serves to weigh, unload, and transport the fruit efficiently to minimize spoilage and ensure optimal processing conditions.

Process:

Trucks loaded with fresh fruit bunches arrive at the mill and are directed to the weighbridge. Once weighed, the fruits are either unloaded manually or tipped hydraulically onto the loading ramp. The fruit is then placed into steel cages or trolleys, which are conveyed to the sterilization area using inclined belts or chain conveyors.

Required Equipment:

- Weighbridge System: Measures the total weight of incoming fruit, ensuring proper yield tracking and purchase verification.

- Loading Ramp: A structured platform where FFBs are collected after unloading, ready for loading into cages.

- Fruit Cages or Trolleys: Durable containers used for holding and moving bunches through the sterilization system.

- Hydraulic Tipper: Mechanized equipment that lifts and tips the truck body to unload large quantities of FFB quickly and safely.

- Inclined Belt or Chain Conveyor: Transfers loaded cages to the sterilization station, minimizing manual labor and accelerating workflow.

Significance:

This stage ensures that the raw materials enter the process pipeline efficiently. Timely reception and transport prevent fermentation and the rise of free fatty acids (FFA), both of which affect oil quality.

Estación de esterilización

Purpose:

Sterilization is a critical heat treatment process that softens the fruit, facilitates fruit detachment from bunches, and inhibits lipolytic enzymes that increase FFA content.

Process:

FFBs loaded into cages are placed inside sterilizers—large pressure vessels—where steam at approximately 145°C is introduced for 60 to 90 minutes. This high-temperature treatment not only makes the fruits easier to thresh but also preserves oil quality by halting biological degradation.

Required Equipment:

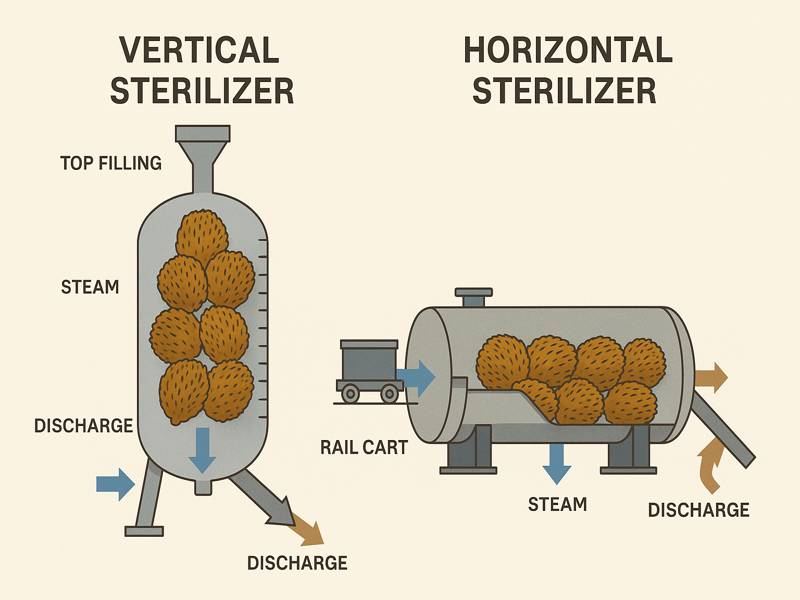

- Horizontal or Vertical Sterilizer: High-pressure vessels designed to withstand steam sterilization cycles. Vertical sterilizers offer space-saving designs, while horizontal units support larger batches.

- Steam Boiler System: Generates and supplies high-pressure steam consistently across all sterilization units.

- Sterilizer Cage: Steel cage designed to hold and transport fruit bunches into the sterilizer chamber.

- Hoist or Crane for Cage Handling: A Mechanized lifting system that positions loaded cages into and out of sterilizers with precision and safety.

- Condensate Recovery Tank: Gathers condensed steam that can be recycled to save water and increase energy efficiency.

Significance:

Sterilization directly influences oil yield and quality. Proper steam distribution and controlled cooking times ensure that fruits are adequately treated without overcooking or underprocessing.

Estación de trilla

Purpose:

After sterilization, palm fruits must be separated from the bunch stalks (rachis). Threshing ensures that only loose fruits proceed to the oil extraction stage, while empty fruit bunches (EFBs) are disposed of or recycled as biomass.

Process:

Sterilized bunches are fed into a rotary drum thresher, where they are agitated by rotating beaters. This action causes the fruits to detach and fall through perforated sections onto a vibrating screen. EFBs exit at the opposite end and are conveyed away.

Required Equipment:

- Rotary Drum Thresher: A cylindrical machine that rotates bunches inside and dislodges the fruits using controlled mechanical impact.

- Vibrating Screen Separator: Filters out impurities, stones, or leftover bunch particles, ensuring clean fruits pass on to the next stage.

- Empty Bunch Conveyor: Moves the discarded EFBs to a collection point, where they can be processed into fuel, mulch, or compost.

Significance:

Efficient threshing maximizes fruit recovery and reduces losses. Automating this stage reduces labor and minimizes damage to the fruit, which helps preserve oil content.

Estación de digestión y prensado

Purpose:

In this station, the goal is to release crude palm oil from the fruit mesocarp. This is done in two steps—first, breaking down the fruit pulp (digesting), then mechanically pressing it to extract the oil.

Process:

The sterilized and threshed fruits are poured into a digester, where they are mechanically stirred and heated to form a homogenous pulp. This pulp is then transferred into a screw press, which compresses the mash to separate oil from fiber and nuts. The result is crude palm oil (CPO) and a solid byproduct known as palm oil cake.

Required Equipment:

- Vertical/Horizontal Digester: Steam-jacketed vessel with internal paddles that mash and heat the palm fruits into a consistent slurry.

- Single Screw or Double Screw Oil Press: The core extraction unit; single screw is common for small-scale operations, while double screw types are used for higher capacity and better yield.

- Oil Collection Tank: Captures and temporarily stores the extracted oil from the press before it moves to clarification.

- Cake Conveyor: Transfers residual solids (press cake) containing nuts and fiber to further processing stations like kernel recovery.

Significance:

Pressing is where the bulk of the oil is recovered. Efficient digester and press design improves extraction rate, reduces oil loss in the cake, and ensures longer equipment lifespan.