Importing palm oil processing equipment can be a complex but rewarding venture, especially for businesses in emerging markets aiming to enhance their palm oil production capacity. Whether you’re establishing a new palm oil mill or upgrading existing facilities, understanding the import process ensures that your investment arrives on time, within budget, and in compliance with all regulations. This article provides a detailed, step-by-step guide to help entrepreneurs, procurement managers, and agribusiness investors successfully import palm oil processing machinery.

1. Understand the Equipment You Need

Before importing, it’s essential to identify the right type of palm oil processing equipment for your business model. The decision is influenced by multiple factors:

- Oil types include palm kernel oil (PKO) and crude palm oil (CPO).

- Production capacity: Small-scale, medium-scale, or industrial-scale operations

- Process stages: Threshing, sterilization, digestion, pressing, clarification, and purification

- Level of automation: fully automated, semi-automated, or manual systems

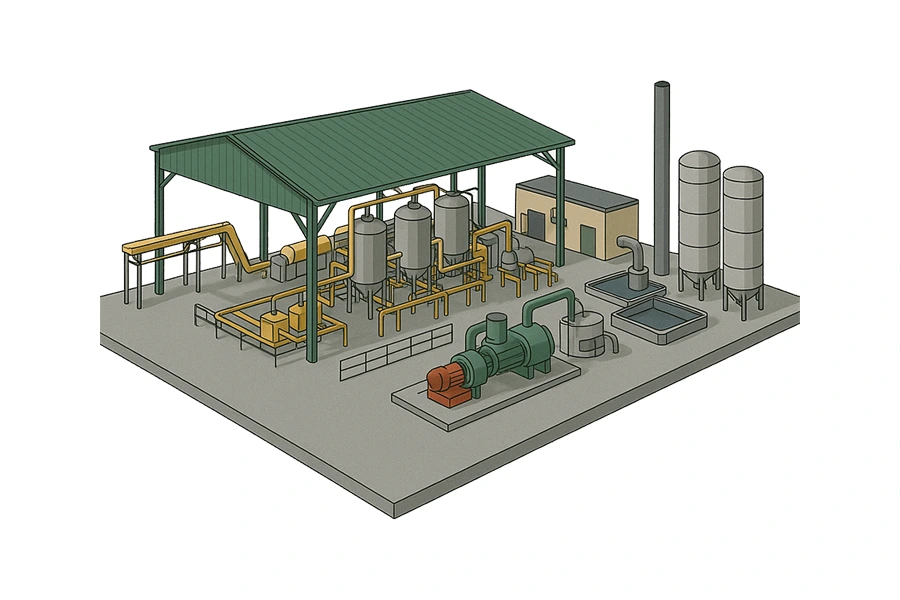

Common Equipment Includes:

- Vertical Sterilizer

- Thresher drum

- Double Screw Oil Press Machine

- Clarification tanks

- Palm kernel cracker and separator

- Nut fiber separator

- Oil filter and vacuum dryer

Compile a detailed list of specifications, capacities, and materials to ensure smooth communication with potential suppliers.

Find a Reliable Supplier

Choosing a trustworthy equipment supplier is crucial. Look for manufacturers or exporters with a solid reputation, technical support, and after-sales service.

How to Evaluate Suppliers:

- Check company certifications: ISO, CE, SGS, etc.

- Read customer reviews and testimonials

- Ask for product catalogs and videos

- Request technical data sheets and warranties

- Verify their export experience and shipping records

Popular Supplier Locations:

- China: Offers cost-effective solutions and a wide variety

- Malaysia & Indonesia: Known for industry-specific designs

- India: Competitive pricing and customization

Request a Proforma Invoice (PI)

Once you’ve selected a supplier, request a Proforma Invoice (PI). This preliminary invoice outlines:

- Product specifications and model numbers

- Unit prices and total cost

- Packaging details (wooden case, container, etc.)

- Delivery terms (EXW, FOB, CIF, etc.)

- Lead time and production schedule

- Payment terms (T/T, L/C, etc.)

- Port of departure and destination

Ensure all technical and commercial details match your requirements before proceeding to payment or shipping.

Confirm Payment Terms and Make Advance Payment

Agree on a secure and suitable payment method. The most common options are:

- Telegraphic Transfer (T/T): typically requires a 70% down payment and 70% prior to shipment.

- Letter of Credit (L/C): more complicated but safer for larger orders

- Trade assurance (for online platforms)

Be cautious of scams. Always verify bank details via phone or video call before transferring funds. Request a sales contract in addition to the PI to formalize the transaction.

Make Shipping Arrangements and Incoterms Clear

Mill operators and research organizations are always looking for methods to increase productivity, cut waste, and improve the quality of their oil. The most common ones include:

- EXW (Ex Works): Buyer arranges everything from factory pickup

- Goods are delivered to the port and cleared for export by the seller using FOB (Free on Board).

- CIF (Cost, Insurance, Freight): Seller handles sea freight and insurance

If you’re inexperienced in international logistics, consider using CIF or CFR, which simplifies the shipping process.

Also, ask the supplier to provide:

- List of packing items

- Business invoice

- Bill of lading (B/L)

- Certificate of origin

Safety documentation and product manuals

Hire a Freight Forwarder or Customs Broker

A freight forwarder coordinates transportation logistics, while a customs broker handles regulatory paperwork. Hiring these professionals ensures smooth customs clearance and delivery.

Services Offered:

- Making a freight reservation via air or sea

- Ensuring correct documentation

- Managing container loading and unloading

- Monitoring the status of shipments

- Managing import taxes and tariffs

- Coordinating final delivery to your warehouse or factory

Look for brokers familiar with palm oil machinery and agricultural equipment importation in your country.

Prepare Import Documentation

To clear customs, you’ll need several documents, which vary slightly depending on your country.

Typical documents consist of:

Required Documents:

- Commercial invoice

List of packing items

As an aviation waybill or bill of lading

License to import (if applicable)

Certificate of origin

Product catalog/manual

Insurance certificate

Proforma invoice or contract

HS Code classification

Some countries require equipment safety certifications or sanitary permits, especially if the machines touch food-grade oil.

Consult with your customs broker early in the process to prepare all documents in advance.

Check Import Duties and Taxes

Understand the import tariffs, VAT, and taxes applicable to your machinery. These costs significantly affect your landed cost.

Ways to Check:

- Visit your country’s customs authority website

- Ask your customs broker

- Use online HS code tariff lookup tools

Some countries offer import duty exemptions or reduced rates for agricultural and food processing equipment. You may need to apply in advance with supporting documents.

Arrange for Inspection and Quality Control

To reduce the risk of receiving faulty or substandard equipment, request Third-Party Inspection (TPI) before shipment. Services like SGS, TUV, or BV can verify:

- Machinery dimensions and specifications

- Functional testing and trial run

- Material and finish quality

- Packaging integrity

Request images or videos of the final packing and assembly process from the supplier. A Pre-Shipment Inspection (PSI) can help avoid surprises on arrival.

Track Shipment and Prepare for Arrival

After dispatch, your supplier or freight forwarder should provide:

- Container number

- Estimated time of arrival (ETA)

- Real-time tracking link

- Scanned copies of shipping documents

Use this information to prepare your warehouse, tools, and installation team for the incoming equipment. Notify local authorities if an inspection is required upon arrival.

Customs Clearance at Port of Entry

Once the shipment arrives, your customs broker will handle:

-

- Document submission to customs

- Duty and tax payments

- Inspection coordination (if needed)

- Bonded warehouse arrangements (if applicable)

Inaccurate or missing papers can cause delays. Double-check every detail beforehand to ensure a smooth release.

Equipment Installation and Commissioning

Once on site, begin installation with the help of:

- Supplier’s technical team (remote or on-site)

- Local engineers or technicians

- Electrical and plumbing contractors

Key steps include:

- Anchoring equipment to the foundation

- Connecting power and water sources

- Aligning belts, shafts, or hydraulic lines

- Lubrication and safety checks

Request a commissioning report and a trial run to ensure functionality. Keep detailed records of operating parameters for warranty claims.

Operator Training and Safety Orientation

Employee training is essential for both long-term performance and security. Ask your supplier to provide:

- User manuals in your local language

- Operational videos

- Troubleshooting guides

- On-site or virtual training sessions

Train workers on:

- Startup and shutdown procedures

- Emergency stop and lockout systems

- Cleaning and maintenance schedules

- Preventive checks and record keeping

Establish Standard Operating Procedures (SOPs) and post them near machinery for reference.

Register Equipment and Apply for Local Certifications

Based on your nation, you could have to:

- Register the equipment with the Ministry of Agriculture or Industry

- Obtain operating permits from health or environmental authorities

- Certify weighing and measurement equipment

- Ensure compliance with food safety or pollution control regulations

Documentation from the supplier—such as test certificates, compliance declarations, and user manuals—will be useful.

Set Up a Maintenance and Spare Parts Plan

To ensure longevity and avoid downtime:

- Maintain a spare parts inventory (seals, belts, filters, etc.)

- Establish a routine maintenance schedule

- Keep detailed service logs

- Set up a relationship with local repair technicians

- Order extra parts during the original shipment to save freight

Communicate with the supplier for ongoing technical support, software updates, or spare part replacements.

Successfully importing palm oil processing equipment requires careful planning, technical knowledge, and coordination across multiple stakeholders—from supplier to customs to local technicians. By following this step-by-step guide, you can minimize risks, avoid costly mistakes, and ensure that your investment yields long-term productivity and profitability.

Whether you’re a first-time importer or expanding your agribusiness, understanding the logistics and compliance landscape will help you build a sustainable, efficient palm oil processing operation.