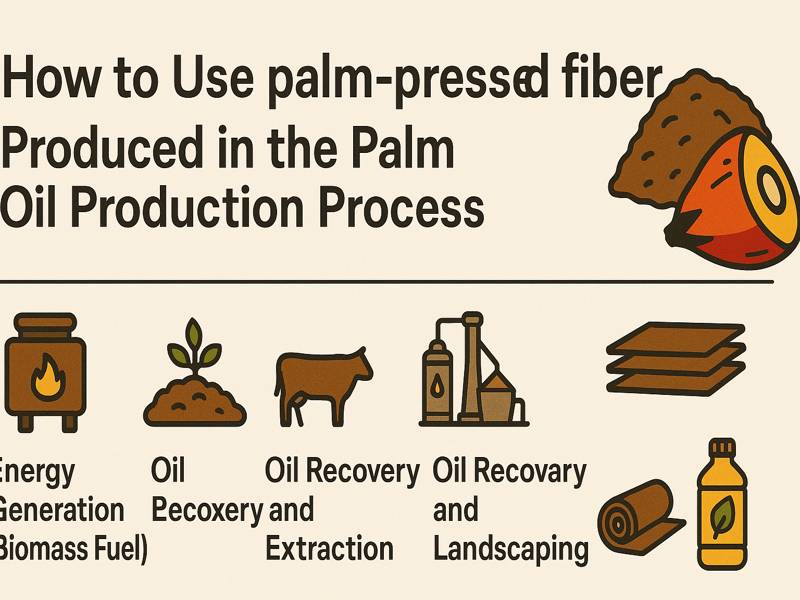

Palm-pressed fiber (PPF), a major by-product of crude palm oil extraction, was once seen as waste. With rising palm oil output, PPF volumes grow—and so do its uses. This article explores its production, composition, and diverse applications, from renewable energy to soil conditioning and animal feed. Utilizing PPF boosts both sustainability and economic value for palm oil mills.

What is Palm-Pressed Fiber?

The biomass left after the palm oil is extracted from the palm oil production process is called palm pressed fiber. It mainly consists of the following components:

- Fibrous mesocarp residues

- Broken shell fragments

- Traces of residual oil

It is produced in large quantities during the mechanical pressing of sterilized oil palm fruits. The fibrous mass is light, brownish in color, and contains significant energy and nutrient content, making it a versatile resource.

Composition and Characteristics of Palm-Pressed Fiber

Understanding the composition of PPF is crucial for identifying its optimal uses. The typical composition includes:

| Component | Percentage (approximate) |

| Moisture | 10–15% (after pressing) |

| Oil | 5–10% |

| Fiber | 60–70% |

| Shells | 10–20% |

| Ash | 1–5% |

Key Properties:

- High lignocellulosic content: rich in cellulose, hemicellulose, and lignin

- Calorific value: ranges between 16-20 MJ/kg

- Residual oil content: can be further recovered or used to enrich products

- Biodegradable and non-toxic

These properties make palm-pressed fiber a candidate for a wide range of industrial and agricultural applications.

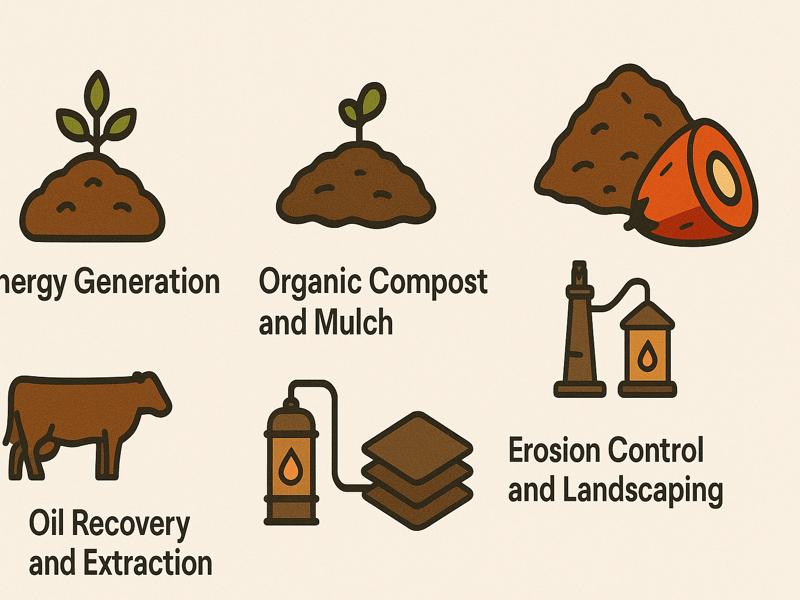

Energy Generation (Biomass Fuel)

One of the most common and valuable applications of PPF is in energy generation. It is used as biomass fuel in palm oil mills for steam production.

Boiler Fuel in Palm Oil Mills

Palm-pressed fiber is often burned in biomass boilers alongside palm kernel shells to generate steam and electricity for mill operations. This internal use reduces dependency on fossil fuels and greenhouse gas emissions.

Co-firing in Power Plants

When properly dried and pelletized, PPF can also be co-fired with coal in thermal power plants. Its high calorific value makes it a renewable alternative fuel in the energy sector.

Briquette and Pellet Production

Compressed PPF can be transformed into briquettes or pellets as solid biofuel for domestic cooking, industrial boilers, or export. This adds commercial value and reduces the environmental impact of biomass disposal.

Organic Compost and Mulch

Palm-pressed fiber is an excellent raw material for composting and mulching due to its organic and fibrous nature.

Soil Amendment

When decomposed, PPF enriches soil organic matter and improves water retention. It can be combined with other mill by-products (like empty fruit bunches and POME) to form high-quality compost.

Mulch for Plantations

Applied as mulch around oil palm or other crops, PPF helps suppress weeds, maintain soil moisture, and reduce erosion. It is particularly useful in replanting schemes to improve young palm growth.

Vermicomposting

PPF can be used as a bedding material in vermicomposting systems, providing a suitable medium for earthworms and accelerating the breakdown of organic waste into nutrient-rich worm castings.

Animal Feed Ingredient

Though fibrous and coarse, palm-pressed fiber has potential as a feed ingredient when processed and combined properly.

Ruminant Feed

PPF can be treated (e.g., ammoniation or fermentation) to enhance digestibility and used as roughage in cattle, goat, and sheep diets. It supplies dietary fiber and energy while reducing feed costs.

Silage Production

Blended with molasses or nitrogen-rich additives, palm-pressed fiber can be ensiled for livestock feeding. The fermentation process helps reduce anti-nutritional factors and improves palatability.

Poultry Litter

Due to its absorbent nature, dried PPF can also serve as a bedding material in poultry houses. After use, the manure-rich litter can be composted and applied as fertilizer.

Oil Recovery and Extraction

Since palm-pressed fiber still contains residual oil (5–10%), many palm oil mills are adopting secondary extraction processes to recover this valuable resource.

Solvent Extraction

Solvents like hexane can be used to extract the remaining oil from the fiber. This recovered oil is often categorized as residual oil and used in industrial products or biodiesel.

Mechanical Screw Press

Double pressing using specialized screw presses can further reduce oil content in the fiber and improve overall oil yield. Though energy-intensive, this method is solvent-free and widely used.

Enzyme-Assisted Extraction

Emerging technologies involve enzyme treatments that help break down fiber cell walls and release entrapped oil. This eco-friendly method is gaining attention for its efficiency and lower chemical use.

Industrial Applications

Thanks to its fibrous structure and organic nature, palm-pressed fiber can be processed into various industrial products.

Pulp and Paper Production

With modifications, PPF can be used to produce paper pulp. Though it has high lignin content, it serves well in low-grade paper applications like packaging or cardboard.

Fiberboard and Panels

PPF is an alternative raw material in the manufacture of medium-density fiberboard (MDF), particleboard, or compressed panels for furniture and building use. It reduces reliance on wood and supports circular economy principles.

Biocomposites

Palm-pressed fiber is being researched as a reinforcement material in biocomposites for automotive parts, packaging, and household items. When combined with polymers, it improves tensile strength and reduces the environmental footprint.

Biochar and Activated Carbon

Through pyrolysis, PPF can be converted into biochar, a carbon-rich material used for soil enhancement and carbon sequestration. With further activation, it becomes activated carbon used in water and air purification.

Landscaping and Erosion Prevention

Applications involving environmental management greatly benefit from palm-pressed fiber.

Erosion Control Mats

PPF can be processed into mats or blankets used on slopes and embankments to prevent soil erosion. These mats support seed germination and biodegrade over time.

Landscaping and Horticulture

Used as a natural mulch or soil conditioner, PPF improves garden aesthetics and soil health. It is a sustainable substitute for synthetic materials due to its biodegradable nature.

Biochemical and Bioplastic Production

Advanced biotechnological processes now allow palm-pressed fiber to be used as feedstock for bio-based materials.

Fermentation Feedstock

The high cellulose content of PPF can be hydrolyzed into sugars, which serve as feedstock for microbial fermentation to produce bioethanol, lactic acid, and other platform chemicals.

Bioplastic Precursors

Derivatives of palm-pressed fiber are being explored for producing biodegradable plastics such as polyhydroxyalkanoates (PHA) and polylactic acid (PLA). This application reduces plastic pollution and creates new revenue streams.

Best Practices for Handling and Processing Palm-Pressed Fiber

To unlock the full potential of PPF, proper handling and preprocessing are crucial:

- Drying: Natural sun drying or mechanical drying is necessary to lower the moisture content and prevent microbial growth.

- Size Reduction: Shredding or grinding the fiber improves its usability in pellets, feed, or composite applications.

- Oil Removal: Prior oil recovery enhances cleanliness and reduces rancidity in end-use applications.

- Storage: Dried and treated PPF should be stored in dry, ventilated spaces to preserve quality and prevent contamination.

- Blending and Conditioning: For feed or compost applications, blending with other materials improves nutritional balance and decomposition rates.

Economic and Environmental Benefits

Using palm-pressed fiber is not just about waste reduction; it’s also a win-win in economic and ecological terms.

Economic Benefits:

- Reduces operational costs by replacing commercial fuels or fertilizers

- Creates additional revenue streams (fiberboard, compost, pellets)

- Lowers waste disposal costs

- Enhances mill sustainability rating (important for global buyers)

Environmental Benefits:

- Minimizes open burning and greenhouse gas emissions

- Reduces dependency on wood and non-renewables

- Promotes closed-loop, zero-waste palm oil production

- Supports rural livelihoods through new industries (composting, animal feed, etc.)

Once viewed as low-value waste, palm-pressed fiber is now vital to sustainable palm oil production. Its renewable, biodegradable nature supports uses in energy, agriculture, and industry. With improved processing and innovation, producers can turn PPF into a profitable, eco-friendly asset, advancing circular economy goals across the industry.