A palm oil production line refers to the integrated process that transforms harvested palm fruit into crude palm oil (CPO) and, in some cases, further into refined palm oil products. This article provides a detailed overview of the stages involved in a typical palm oil production line, key machinery, and best practices for efficiency and sustainability.

Introduction to Palm Oil Production

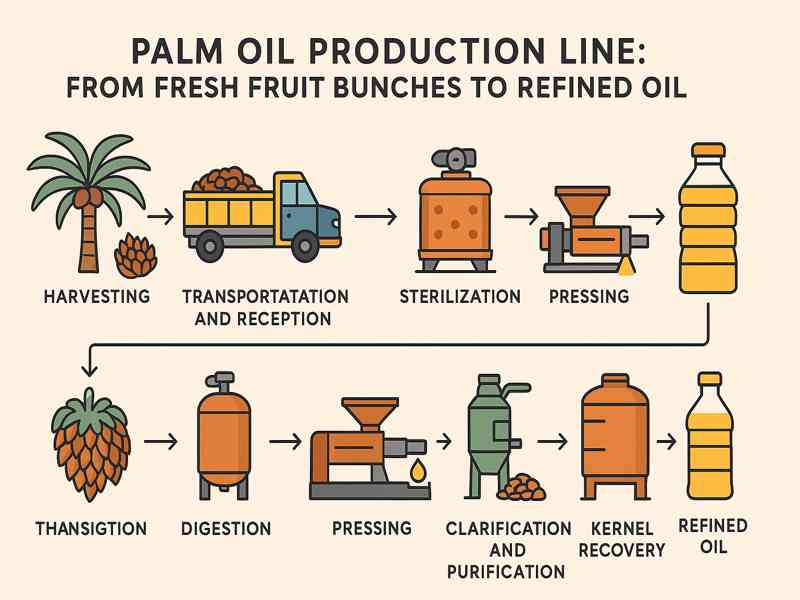

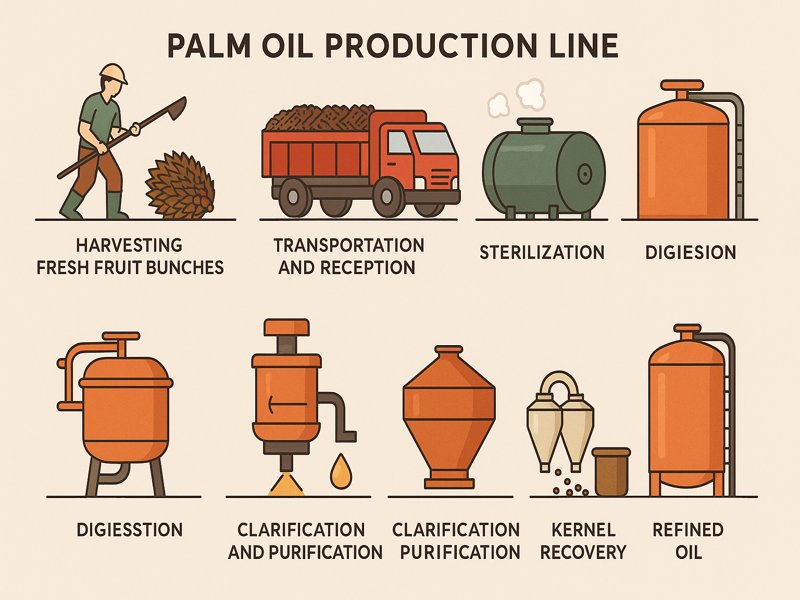

Palm oil is extracted from the mesocarp, or fleshy part, of the oil palm fruit (Elaeis guineensis). The production process begins at the plantation with the harvesting of fresh fruit bunches (FFBs) and ends with refined palm oil ready for packaging or further industrial use. The palm oil production line can be divided into three main stages:

- Primary processing – from FFBs to crude palm oil

- Secondary processing – refining crude palm oil

- By-product recovery and treatment – managing kernels, effluent, and biomass

Step-by-Step Breakdown of the Palm Oil Production Line

Step 1: Harvesting Fresh Fruit Bunches (FFBs)

- Process: FFBs are harvested manually or mechanically from oil palm trees once they ripen, typically every 10 to 15 days.

- Considerations: Timely harvesting is essential. Overripe fruit loses oil content; underripe fruit gives poor oil yield.

Step 2: Transportation and Reception

- Process: Harvested FFBs are transported to the palm oil mill via trucks, lorries, or rail.

- Reception Station: A weighbridge is used to log incoming loads. FFBs are unloaded into large reception ramps or hoppers.

Step 3: Vertical Sterilizer

- Purpose: Steam sterilization deactivates enzymes, loosens fruits from bunches, and softens the mesocarp for easier oil extraction.

- Method: FFBs are loaded into horizontal or vertical sterilizer tanks and exposed to saturated steam (140–145°C) for 60–90 minutes.

- Benefits: Prevents free fatty acid (FFA) buildup and facilitates stripping.

Step 4: Thresher Drum

- Process: Sterilized bunches are fed into rotating drum threshers or stripper cages to separate fruit from the bunch stalks.

- Output: Loose fruits proceed to digestion; empty fruit bunches (EFBs) are sent for composting or biomass fuel.

Step 5: Digester

- Function: The loose palm fruits are mashed to rupture oil cells and prepare them for pressing.

- Equipment: Steam-jacketed digesters with rotating arms.

- Duration: 20–30 minutes at around 90–100°C.

Step 6: Double Screw Oil Press Machine

- Method: Crushed fruit mash is fed into screw presses to extract crude palm oil (CPO).

- Outcome: The process yields a mixture of oil, fiber, and nuts. The oil-rich mixture is sent for clarification.

Step 7: Clarification and Purification

- Primary Separation: Crude oil from the press is allowed to settle in a tank to remove solids and water.

- Centrifugation: Separates oil from water and sludge.

- Purification: Additional tanks heat and filter the oil to remove remaining impurities.

- Output: Clean crude palm oil (CPO), which is sent to storage or refining.

Step 8: Kernel Recovery

- Nut and Fiber Separation: Press cake from the screw press is separated via blowers and cyclones.

- Nut Cracking: Nuts are cracked to separate shells from kernels.

- Kernel Drying: Kernels are dried and stored for palm kernel oil (PKO) extraction.

Step 9: Oil Storage

- Tanks: CPO is stored in heated stainless steel tanks to maintain fluidity and prevent spoilage.

- Preparation for Dispatch: Oil is either sold as crude or pumped into the refining line.

Palm Oil Refining (Secondary Processing)

Once crude palm oil is obtained, it can be refined to meet food-grade or industrial standards. Refining involves three main steps:

a. Degumming and Neutralization

Removes phospholipids, FFAs, and gums using phosphoric acid and caustic soda.

b. Bleaching

Removes color pigments using activated clay or earth.

c. Deodorization

High-temperature steam distillation under vacuum removes odors and residual FFA.

The final product is Refined, Bleached, and Deodorized Palm Oil (RBDPO), suitable for cooking oil, margarine, or further fractionation.

Supporting Systems and By-product Utilization

Efficient palm oil production lines include systems to handle and reuse by-products:

a. Palm Kernel Oil Extraction

Kernels are crushed to yield palm kernel oil and cake (used in animal feed).

b. Palm Oil Mill Effluent (POME) Treatment

POME contains a high organic load and is treated using anaerobic and aerobic digestion ponds or biogas systems.

c. Use of Biomass

EFBs, fibers, and shells are burned in boilers to create steam and energy for mill operations.

Key Equipment in Palm Oil Production Line

| Process Stage | Equipment Type |

| Reception | Weighbridge, loading ramp |

| Sterilization | Horizontal/vertical sterilizer |

| Threshing | Thresher drum |

| Digestion | Steam-jacketed digester |

| Pressing | Screw press |

| Clarification | Settling tank, centrifuge |

| Kernel Recovery | Cyclone separator, cracker |

| Refining | Degumming tank, bleaching tower |

| Power & Utilities | Boilers, turbines |

| Waste Management | Effluent treatment system |

Efficiency and Sustainability Considerations

To optimize performance and reduce environmental impact, palm oil producers must incorporate sustainable practices into the production line.

a. Energy Efficiency

- Recover steam condensate

- Use biomass boilers with fiber and shell as fuel

b. Water Conservation

- Recycle process water where possible

- Install closed-loop systems in clarification and boiler feedwater systems

c. Waste Management

- Compost EFBs as organic fertilizer

- Treat POME to avoid groundwater pollution

- Capture biogas for clean energy use

d. Automation and Digital Monitoring

- Use SCADA systems for process control

- Install online sensors for FFA, moisture, and temperature monitoring

- Implement predictive maintenance systems

Layout and Factory Planning Tips

A well-organized production layout ensures material flow, reduces downtime, and enhances safety. Key layout recommendations include:

- Place sterilizers near the reception to reduce FFB deterioration.

- Position presses and digesters centrally for efficient material transfer.

- Build effluent ponds and composting zones downwind and downstream.

- Allocate zones for kernel processing, oil storage, boiler house, and maintenance.

- Reserve space for future expansion and biogas systems.

Quality Control and Certifications

Maintaining product quality is critical. Key steps include:

- Monitoring FFA levels regularly

- Using food-grade stainless steel tanks and pipes

- Conducting routine oil sampling and laboratory testing

- Complying with certifications like:

- RSPO (Roundtable on Sustainable Palm Oil)

- ISO 22000 / HACCP for food safety

- ISCC (International Sustainability and Carbon Certification)

Output Yields and Processing Capacity

| Parameter | Typical Yield (%) |

| Crude Palm Oil (CPO) | 20–23% of FFB |

| Palm Kernel | 4–6% of FFB |

| Empty Fruit Bunch (EFB) | 20–23% of FFB |

| Fibre and Shells (Biomass) | 13–15% of FFB |

| POME | 50–60% of FFB |

Small-scale mills process 1–5 tons of FFB per hour, while large industrial plants handle 30–100+ tons/hour.

A palm oil production line is a complex but highly efficient system designed to extract maximum value from every ton of fresh fruit. From harvesting and sterilization to refining and waste utilization, every step must be carefully managed for optimal yield, quality, and sustainability.

If you are interested in this palm oil processing equipment, please feel free to contact us! Vortech Global‘s professional engineers will recommend palm oil processing equipment that suits your needs.