Palm oil has become one of the most widely used edible oils in the world, driving demand for efficient processing technologies. Whether you’re a smallholder farmer, mid-size factory owner, or industrial-scale investor, understanding the cost of palm oil processing machines is crucial to making an informed purchase decision.

Why the Cost of Palm Oil Machinery Varies Widely

The price of palm oil equipment is not set in stone; rather, it varies greatly based on a number of factors:

- Processing Capacity (tons/hour or tons/day)

- Level of Automation (manual, semi-automatic, or fully automatic)

- Machine Components and Configuration

- Material Quality and Build

- Technology and Efficiency

- Brand, Warranty, and After-Sales Service

A small-scale processing unit could cost as low as $2,000–$8,000, while an industrial setup with full automation might exceed $500,000.

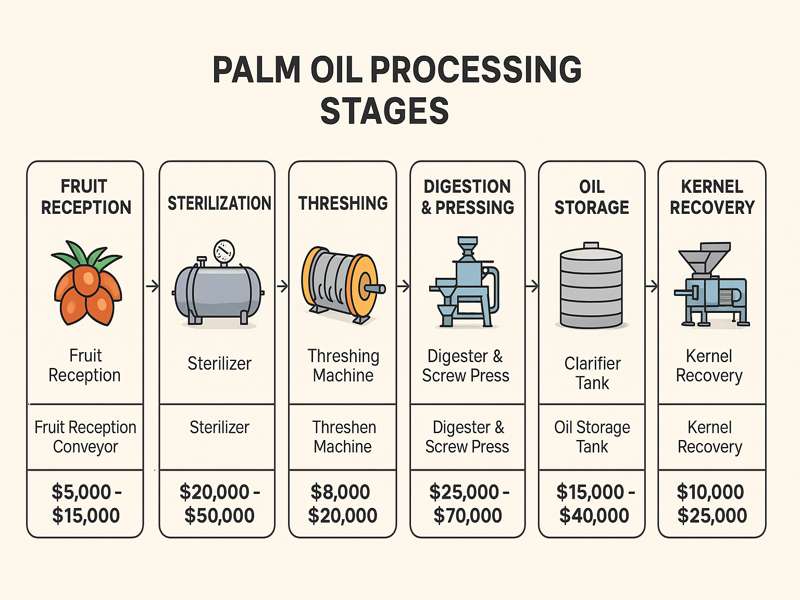

Cost Breakdown by Machine Type

Here is a typical cost range by major equipment type:

| Equipment | Function | Typical Price Range (USD) |

| Fruit Bunch Thresher | Separates fruit from bunches | $2,000 – $30,000 |

| Sterilizer Tank (Horizontal/Vertical) | Steam treatment to loosen the fruit | $3,000 – $100,000+ |

| Digester & Screw Press | Mashes fruit and extracts crude oil | $4,000 – $60,000 |

| Oil Clarification Unit | Removes impurities and sludge | $1,500 – $40,000 |

| Oil Dryer | Reduces the moisture content in CPO | $1,000 – $15,000 |

| Kernel Recovery Unit | Extracts and separates palm kernel | $3,000 – $25,000 |

| Boiler (Steam Generation) | Powers sterilizer and digester | $10,000 – $80,000 |

| Empty Bunch & Effluent Handling | Waste management system | $5,000 – $40,000 |

These prices vary by region, supplier, and material specification.

Cost by Processing Capacity

Capacity is one of the biggest cost drivers:

Small-Scale (500kg–1 ton/hour)

- Ideal for cooperatives and rural mills.

- Typically priced between $5,000 and $30,000.

- Often includes a thresher, digester, screw press, and small clarification system.

Medium-Scale (2–5 tons/hour)

- Suitable for village or regional production.

- Price ranges from $50,000 to $200,000.

- Includes improved automation, larger presses, and better effluent treatment.

Industrial-Scale (10+ tons/hour)

- Designed for commercial and export-grade processing.

- Total plant setup can exceed $300,000 to $1 million, depending on automation.

- Features include advanced kernel recovery, energy recovery systems, and environmental compliance modules.

The Role of Automation in Cost

Automation can double or triple the cost, but it often pays off:

| Automation Level | Features | Cost Impact |

| Manual | Requires high labor input | Low initial cost, higher labor |

| Semi-Automatic | A mix of manual loading and auto controls | Mid-range cost and efficiency |

| Fully Automatic | PLC-controlled, remote monitoring | High cost, minimal labor, efficient |

For instance, a semi-automatic 3 TPH line might cost $120,000, while a fully automatic version of the same could exceed $220,000.

Installation and Ancillary Costs

The machine cost is just part of the equation. Other associated costs include:

- Shipping & Customs: $1,000 – $20,000 depending on location and container size.

- Installation & Commissioning: 10%–15% of total machine cost.

- Civil Works (Factory & Foundation): Varies by region; could be $5,000 – $50,000+.

- Power Supply Setup: Transformers, wiring, diesel generators, etc., range from $2,000 to $50,000.

- Water Treatment and Waste Management: Especially important for environmental compliance.

Together, these ancillary expenses can add 20%–50% to the total investment.

Build Material and Engineering Quality

Higher-quality steel and branded electrical components significantly influence cost.

| Build Quality | Impact on Cost |

| Mild Steel (MS) | Lower cost, less corrosion resistance |

| Stainless Steel (SS304/316) | Higher cost, better durability |

| Branded Motors (ABB, Siemens) | Raise cost, but improve reliability |

Some low-cost machines use thin metal and generic motors, reducing durability. It’s better to invest upfront than face frequent repairs.

Customization Costs

Certain buyers require custom features, which increase cost:

- Dual-fuel or biomass boilers (+$10,000–$30,000)

- Remote control & monitoring systems (+$5,000–$20,000)

- Stainless steel food-grade build (+20%–50% overall)

- Modular design for scaling up later (+10%–15%)

Customization helps future-proof your investment, but must be budgeted upfront.

Maintenance and Operating Costs

Ongoing costs often determine long-term ROI:

| Cost Type | Typical Range (Annual) |

| Spare Parts | $500 – $10,000 |

| Lubricants & Consumables | $1,000 – $5,000 |

| Labor | Based on size (e.g., $500/month per worker) |

| Electricity/Diesel | $5,000 – $50,000 |

| Waste Treatment | $2,000 – $20,000 |

Investing in machines with low operating costs and easy maintenance can save tens of thousands over the machine’s lifespan.

Tips for Budgeting Your Palm Oil Machine Purchase

Here’s how to plan effectively:

- Start with your production target (liters/day or tons/hour)

- Consult at least 2–3 reputable suppliers for quotes

- Don’t ignore installation and utility costs

- Ask about warranties and after-sales support

- Make a spare part inventory plan in advance.

- Examine the entire cost of ownership rather than simply the purchase price.

Avoid underbudgeting for key components like boilers, dryers, and waste systems, which are essential for compliance and continuous operation.

Leading Suppliers and Cost Benchmarks

Popular global and regional equipment manufacturers include:

| Company | Country | Target Market |

| Alfa Laval | Sweden | Large-scale, high-end |

| Besteel | Malaysia | Medium to large mills |

| Vortech Global | China | Multi-industry OEM |

| Muar Ban Lee (MBL) | Malaysia | Modular and scalable |

| Goyum Group | India | Small to mid-range |

| Henan Glory Company | China | Budget and mid-tier |

Prices can differ by 10%–30% across suppliers with similar specs—get detailed BOM (Bill of Materials) comparisons to assess value.

Government Subsidies and Funding Options

Many countries with palm oil industries—such as Indonesia, Nigeria, Malaysia, and Ghana—offer subsidies or grants to promote agricultural processing:

- Smallholder financing programs

- Equipment import tax exemptions

- Green tech loans for sustainable mills

- Development bank funding for agri-industrial investments

Check with your local Ministry of Agriculture, cooperative banks, or UN/FAO development programs.

Whether you’re launching a small community-based mill or expanding an industrial operation, the real question isn’t “What’s the cheapest machine I can buy?” but “Which machine gives me the best value over time?”