Entering the palm oil industry offers great potential for first-time agribusiness entrepreneurs. Palm oil and palm kernel oil open doors to food, cosmetic, biofuel, and industrial markets. But the key decision lies in choosing between crude palm oil (CPO) extraction from the fruit’s flesh or palm kernel oil (PKO) processing from the seed.

Knowing the Fundamentals: Palm Kernel Oil vs. Palm Oil

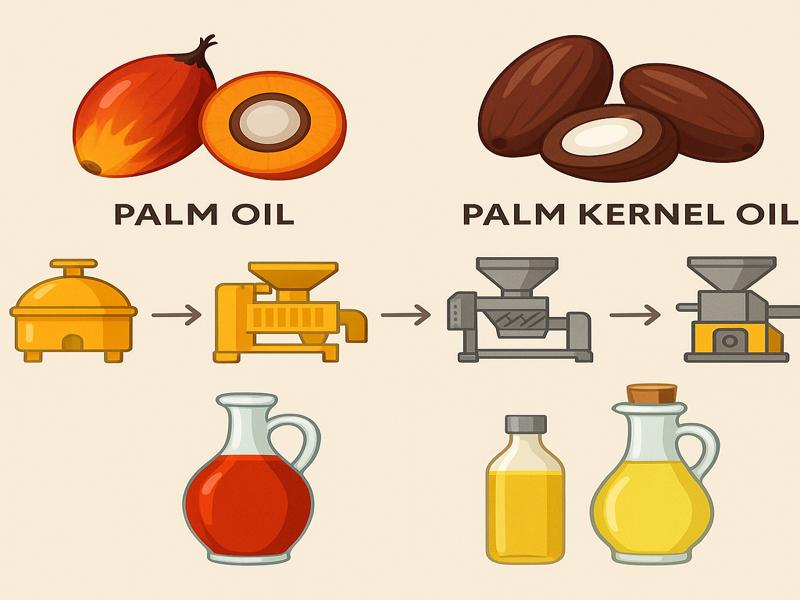

Palm Oil (Crude Palm Oil – CPO)

The oil palm fruit’s meaty mesocarp is where palm oil is derived. It is semi-solid at room temperature and has a scarlet hue because of its high beta-carotene content.

Main Uses:

- Cooking oil

- Margarine, as well as shortening

- Processed foods

- Biofuels

- Cleaners and Soaps

Palm Kernel Oil (PKO)

The kernel or seed of the oil palm fruit is where palm kernel oil is produced. It is lighter in color, has a higher saturation level, and is used more in non-edible products.

Main Uses:

- Personal care and cosmetics (lotions, creams)

- Detergents and soaps

- Industrial lubricants

- Specialty fats (e.g., cocoa butter substitutes)

Though both come from the same fruit, the processing techniques, equipment, and market characteristics vary significantly.

Raw Material Availability and Cost

Palm Oil Processing

- Source: Fresh fruit bunches (FFBs)

- Extraction: Directly from the mesocarp after sterilization and digestion

- By-products: Palm kernel (used in PKO), palm-pressed fiber, and palm oil mill effluent (POME)

FFBs are abundant in palm-growing regions. First-time entrepreneurs located near plantations have easy access to raw material.

Palm Kernel Oil Processing

- Source: Palm kernel (from CPO by-product)

- Extraction: Requires drying, cracking, separating the shell from the kernel, and then pressing or solvent extraction

- By-products: Palm kernel cake (PKC), useful for animal feed

PKO relies on CPO processing as an upstream source. Therefore, setting up a palm kernel oil business may depend on purchasing palm kernels from palm oil mills, making it slightly more complex for beginners.

Winner for First-Time Entrepreneurs:

✅ Palm oil, due to direct raw material availability and fewer processing dependencies.

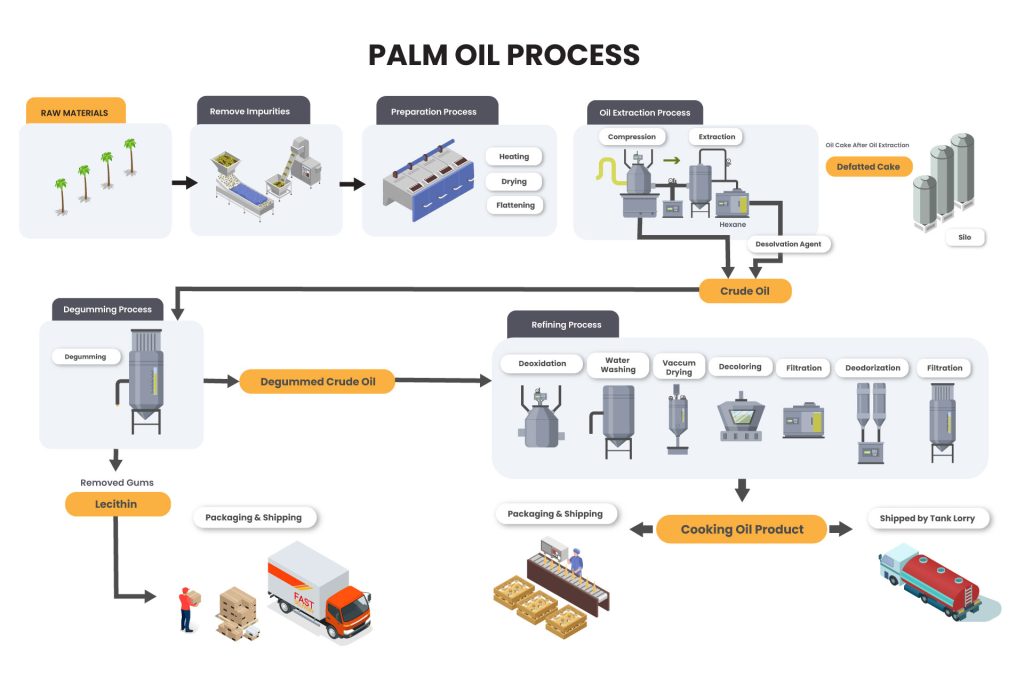

Processing Methods and Equipment Complexity

Palm Oil Processing Equipment

- Main Steps: Sterilization → Stripping → Digestion → Pressing → Clarification

- Equipment Needed: Vertical Sterilizer, Thresher Drum, Digester, Double Screw Oil Press Machine, clarification tank, storage tanks

- Technology Level: Available in mini, semi-automatic, and fully automated setups

Palm oil processing is relatively straightforward and can be scaled from manual small-scale units to industrial plants. Many equipment suppliers offer turnkey mini palm oil mills tailored for small investors.

Palm Kernel Oil Processing Equipment

- Main Steps: Nut drying → Cracking → Shell separation → Pressing/solvent extraction → Filtration

- Equipment Needed: Nut dryer, kernel cracker, separator, oil expeller, filter press

- Technology Level: Typically more specialized and capital-intensive

PKO processing involves kernel shell separation, which requires higher mechanical precision to minimize kernel loss. Solvent extraction also adds safety and environmental considerations.

Winner for Simplicity and Ease of Setup:

✅ Palm oil, due to simpler and more modular machinery options.

Capital Investment and Operating Costs

Palm Oil Processing

- Initial Investment: $8,000–$30,000 for mini mills

- Operating Costs: Moderate (energy, labor, water)

- Maintenance: Routine mechanical maintenance, easy-to-train workers

- Profit Margins: Decent, with demand across food and fuel sectors

Small-scale palm oil mills can start with modest budgets, using batch or semi-automated equipment. Operational costs are manageable, especially if you’re near plantations or have a steady FFB supply.

Palm Kernel Oil Processing

- Initial Investment: $15,000–$50,000 for complete setup

- Operating Costs: Higher due to cracking, shell separation, and filtration

- Maintenance: Frequent attention to the cracking and separation of units

- Profit Margins: Higher per liter, but supply chain costs offset benefits

PKO businesses often require greater upfront capital, especially if solvent extraction is involved. Efficient operations demand a steady kernel supply and skilled labor.

Winner for Cost Efficiency and Entry-Level Feasibility:

✅ Palm oil, especially for limited-capital entrepreneurs.

Market Demand and Product Versatility

Palm Oil Market

- Global Consumption: Over 70 million metric tons annually

- Consumers: Food processors, biodiesel producers, cooking oil companies

- Price Trends: Stable with moderate growth

- Export Potential: Strong in Asia, Africa, and the Middle East

Palm oil has broad appeal, especially in domestic cooking oil markets. Demand is consistent, making it ideal for new entrants.

Palm Kernel Oil Market

- Niche Demand: Cosmetics, soap making, specialty fats

- Buyers: Personal care manufacturers, niche food sectors

- Price Trends: Higher value per unit but more volatile

- Export Potential: Strong in cosmetic and luxury product markets

While PKO earns higher prices per liter, its market is narrower and more competitive, especially for exporters.

Winner for Broad and Stable Market Reach:

✅ Palm oil, thanks to its staple food role and energy applications.

Value-Added By-Products and Revenue Streams

Palm Oil Business

By-products:

- Palm Kernel (sold to PKO processors)

- Palm-pressed fiber (used as biomass or compost)

- Empty fruit bunches (EFBs)

- POME (used in biogas production)

Additional opportunities: sell FFB waste as fuel, compost, or livestock feed. Some entrepreneurs start biogas or organic fertilizer production alongside.

Palm Kernel Oil Business

By-products:

- Palm Kernel Cake (PKC): High-protein animal feed

- Residual fiber (used in compost)

- Spent cake (sold to feed mills or energy plants)

PKO producers often generate high-value PKC, which is in demand for animal feed. However, extracting and drying it requires extra equipment and energy.

Winner for Diversification Potential:

🤝 Tie, depending on which by-product markets are stronger in your area.

Environmental and Regulatory Considerations

Palm Oil Mills

- Environmental Concerns:

POME discharge (needs treatment)

FFB waste disposal

Odor and emissions from sterilization

- Regulatory Requirements: Compliance with local wastewater, safety, and zoning laws

Palm Kernel Oil Plants

- Environmental Concerns:

Dust from cracking operations

Solvent handling (if applicable)

Higher electricity use

- Regulatory Requirements: May require chemical handling permits, especially for solvent plants

Winner for Lower Regulatory Burden:

✅ Palm oil, especially for small mechanical presses without solvent use.

Scalability and Business Growth

Palm Oil

- Easy to start small and expand

- Additional units (presses, digesters) can be added

- Integrated plantations and contract farming models are possible

- Compatible with cooperative or community-based ventures

Palm Kernel Oil

- Requires a consistent kernel supply for expansion

- Specialized equipment upgrades may require more space

- Suitable for vertical integration (oil + cake + cosmetics)

Winner for Progressive Scale-Up:

✅ Palm oil, especially for grassroots and rural entrepreneurship.

Final Comparison Table

| Criteria | Palm Oil Processing | Palm Kernel Oil Processing |

| Raw Material Availability | Easy (FFB directly used) | Depends on palm oil mills |

| Machinery Complexity | Simple to moderate | Moderate to high |

| Startup Capital | Lower ($8k–$30k) | Higher ($15k–$50k) |

| Operating Cost | Moderate | Higher |

| Market Reach | Broad, staple use | Niche (cosmetics, detergents) |

| Price Per Liter | Lower but stable | Higher but volatile |

| By-product Value | Kernel, biomass, POME | PKC, residual cake |

| Environmental Requirements | Easier compliance | Stricter if solvents used |

| Ideal for First-Time Entrepreneurs | ✅ Yes | ❌ Requires experience or niche focus |

Which Is Better for First-Time Entrepreneurs?

For first-time entrepreneurs entering the palm oil industry, starting with palm oil processing offers a lower-risk, more scalable, and broadly accepted business model.

Its advantages include:

- Easier access to raw materials

- Simplified processing equipment

- Flexible startup costs

- Broader local and export markets

- Straightforward regulatory compliance

Palm kernel oil, while profitable, is more suited for experienced entrepreneurs or those with specific product or export targets, such as organic beauty brands or feed manufacturers.

Final Verdict:

👉 Start with Palm Oil Processing.

Then, as your business grows and matures, consider diversifying into Palm Kernel Oil to increase profitability and market reach.