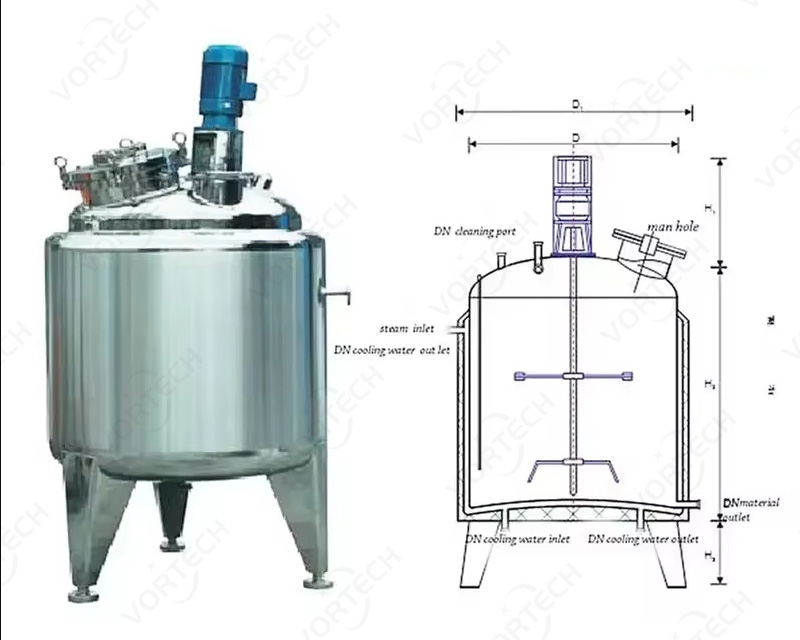

Stainless Steel Mixing Tank

- Volume: 100Liters

- SUS304 stainless steel structure.

- Tri-layer structure, steam heating or electric heating mode, insulated and jacketed.

- Mounted with agitator, CIP cleaning ball, and breather valve.

- A mixing tank to mix with other ingredients for sauce making, as well to sterilize the product inside by steam heating.

- Dimension(L*W*H): 520*520*900mm

- E-mail: sales@vortechglobal.com

- Categories: Tomato Processing Machine, Vacuum Evaporation Section

- Inquiry Now

Product Details

Ensures uniform mixing of ingredients and sterilizes the tomato paste, eliminating harmful microorganisms and ensuring the paste is safe for consumption while maintaining its flavor and quality.

Process It Belongs To:

- The post-processing stage, specifically after concentration, blends the tomato paste evenly and ensures it undergoes sterilization before packaging.

Related Equipment Before:

- Concentrates the tomato paste by removing excess moisture under vacuum, preserving flavor, color, and nutrients.

- Supplies concentrated tomato paste directly to the mixing tank for further homogenization and potential sterilization.

- Holds concentrated paste before it moves into the mixing process.

- Feeds the paste into the Stainless Steel Mixing Tank on demand, ensuring a stable supply and preventing production delays.

Related Equipment After:

Viscous Product Filling Machine

- Fills sterilized and uniformly mixed tomato paste into jars, pouches, or containers.

- Draws product directly from the tank (if sterilization is complete) or post-sterilization unit for hygienic and accurate filling.

Product Parameter:

| Material | SUS304 |

| Working Capacity | 50L to 20000L, even more large. |

| Operate pressure | Atmosphere |

| Layer | Single/ Double(heating)/ Three layers(Insulation); |

| Thickness | 2mm- 12mm |

| Heating or cooling |

|

| Top | Dome, conical top, or flat |

| Bottom | Dome, conical top, or flat |

| Impeller type | Paddle /propeller/anchor / magnetic stirrer / high shear homogenizer mixer |

| Stirring speed (rpm) | 0-300 |

| Polishing | Mirror polish inside and outside |

| Component

(Optional) |

|