Palm Oil Equipment Supplier

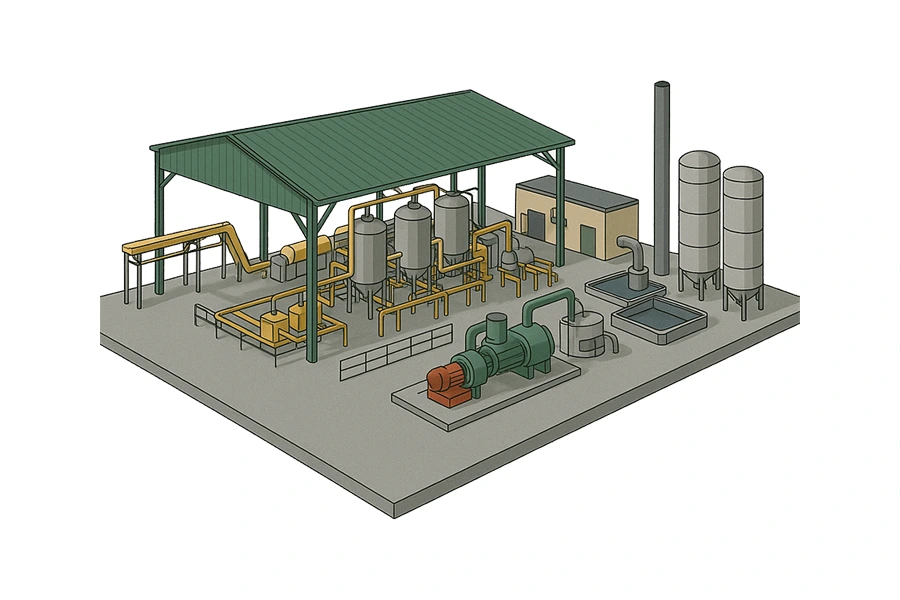

- Vortech Global is dedicated to offering customers a comprehensive range of integrated solutions for food processing production equipment.

- Whether you want to open a small palm oil mill or expand an existing mill, our team can provide turnkey project services, covering everything from site assessment, mill layout design to equipment manufacturing, installation and technical training.

- High Oil Extraction Efficiency

- Complete Processing Line Solutions

- Low Maintenance & Easy Operation

- Customizable for Any Scale

What Equipment can we provide for Palm Oil Production Line?

Raw Materials Reception Station

Receive and weigh fresh fruit bunches (FFB), then unload by tipper or manually. Convey cages to sterilization to reduce spoilage.

Required Equipment

- Weighbridge System

- Loading Ramp

- Low Maintenance & Easy Operation

- Hydraulic Tipper

- Inclined Belt or Chain Conveyor

Weighbridge Systems

Weighbridge systems accurately record the weight of fresh fruit bunches (FFBs), providing important data for yield tracking and transaction transparency.

Fruit Cages or Trolleys

Fruit cages or trolleys are used to store and transport fresh fruit bunches (FFBs). They can support heavy loads without deforming due to their corrosion-resistant construction.

Inclined Belt or Chain Conveyor

This conveyor moves fruit cages or FFB to sterilization, with durable, corrosion-resistant parts for continuous use.

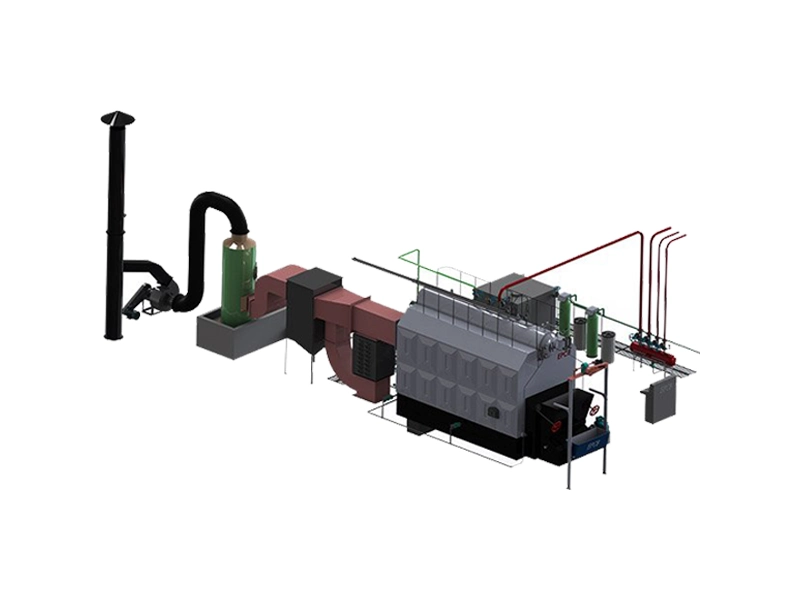

Sterilization Station

Sterilization cooks FFB at 145°C (60–90 mins) to reduce FFA and ease separation. Our boiler ensures steady heat to prevent oil solidification.

Required Equipment

- Horizontal or Vertical Sterilizer

- Steam Boiler System

- Sterilizer Cage

- Hoist or Crane for Cage Handling

- Condensate Recovery Tank

Horizontal or Vertical Sterilizers

Used to cook fresh fruit bunches (FFB) at 145°C for 60 to 90 minutes, available in horizontal or vertical configurations and equipped with a pressure-resistant, insulated chamber to retain heat and ensure uniform steam penetration.

Steam Boiler Systems

Provide high-pressure, high-temperature steam required for palm fruit sterilization. For steady, uninterrupted heat delivery. Prevents undercooking and solidification of the oil, thereby maintaining overall processing efficiency and oil quality.

Sterilization Cages

Carry and transport batches of fresh FFB in and out of the sterilization chamber, made of heavy-duty heat-resistant steel, capable of withstanding repeated high temperatures and pressures. Ensures safe and orderly batch processing.

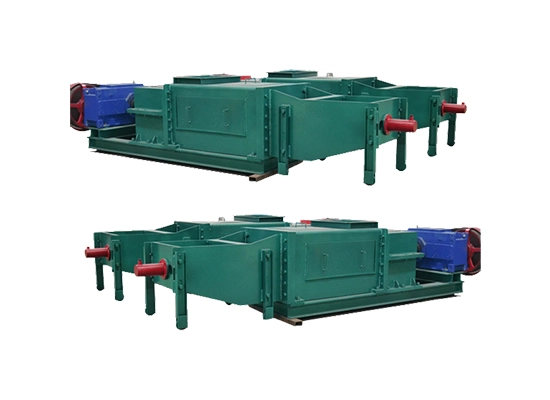

Threshing Station

The palm fruit is separated from the fruit bunches by mechanical means; the fruit is transported to the next process through the under thresher conveyor, and the empty fruit bunches are discharged.

Required Equipment

- Rotary Drum Thresher

- Vibrating Screen Separator

- Empty Bunch Conveyor

Rotary Drum Thresher

A rotating cylindrical drum with a built-in lifting device made of wear-resistant steel is used to stir the fruit bunches to make the fruit fall off, with an adjustable speed and to minimize the damage to the fruit pulp.

Vibrating Screen Separator

Located below the thresher, it filters out fine debris, stem fragments and undersized particles from the fruit through high-frequency vibration and multi-layer mesh screens.

Empty Bunch Conveyor

A chain or belt mechanism is usually used to handle large pieces of fibrous materials, automatically remove empty bales, and convey the fruit bunch residue discharged by the thresher.

Digesting & Pressing Station

The palm fruit is pounded in a digester to obtain a homogenous blend of the pulp. After that, crude palm oil (CPO) is extracted from the palm fruit paste using a screw press, leaving behind palm oil cake.

Required Equipment

- Vertical/Horizontal Digester

- Single Screw or Double Screw Oil Press

- Oil Collection Tank

- Cake Conveyor

Vertical/Horizontal Cooker

The palm fruit is crushed and mashed using carbon steel reamers to break down the mesocarp tissue and loosen the oil-bearing cells. A steam coil is built in to allow steam to be introduced to prevent the palm oil from condensing in the tank.

Single or Double Screw Oil Press

The reducer, hydraulic pump station and oil press work together to apply continuous pressure through the screw shaft to extract crude palm oil (CPO) from the mashed pulp and discharge the intact palm fruit kernel.

Oil Collection Tank

Located below the oil press, it collects the extracted crude palm oil for further clarification. Made of stainless steel or food-grade steel, it is usually equipped with a drain valve and mesh screen for initial sedimentation and removal of debris.

Oil Clarification Station

The extracted oil undergoes settling, centrifugation, and filtration to remove impurities and produce clean, saleable crude palm oil.

Required Equipment

- Clarification Tank

- Oil Skimme

- Vibrating Screen

- Sludge Tank and Pump

- Plate And Frame Filter Press

Clarification Tank

Use gravity to settle crude palm oil and separate it from water, solids and sludge. Adopt heating coil and insulation wall design to maintain optimal temperature for efficient separation.

Vibrating Screen

Use double-layer stainless steel screen, 20 mesh on the upper and 40 mesh on the lower, high-frequency vibration and tilting design to filter out coarse particles, fibers and debris.

Plate and Frame Filter Press

Perform final filtration to remove 99% of impurities in clarified oil. It is made of corrosion-resistant filter plates and replaceable filter cloths to achieve high filtration accuracy of crude palm oil.

Custom Factory Planning Services

We offer custom factory planning, equipment design, turnkey support, and optimization solutions for efficient, compliant, and scalable palm oil mill operations.

Customized Equipment Selection & Plant Design

- Tailor processing line according to FFB capacity, land size, and budget.

- Offer modular design options for smallholder mills or scalable upgrades.

- Provide 2D/3D plant layout drawings specific to palm oil flow.

Turnkey Project Support

- Full EPC service: Engineering, Procurement, and Construction for palm oil mills.

- Support from site planning to commissioning and worker training.

- Integration of all machines from sterilizer to oil storage in one efficient flow.

Specialized Machinery Manufacturing

- Design and manufacture palm-specific machines.

- Use of stainless steel, anti-corrosive materials for food-grade compliance.

Palm Oil Optimization Solutions

- Provide lab-tested screw press and digester configurations optimized for palm oil yield.

- Recommend settings for low Free Fatty Acid (FFA) oil preservation.

- Steam pressure and cycle time tuning for better sterilization efficiency.

Technical Training & Operation Manuals

- On-site or remote training tailored to palm oil mill operations.

- SOPs for every stage: sterilization, pressing, clarification, and kernel recovery.

- Multilingual documentation for easier adoption.

Biomass Waste Recovery Solutions

- Design systems for using empty fruit bunches, fibers, and shells as biomass fuel.

- Supply EFB presses, fiber shredders, and shell-fired boilers.

Environmental Compliance & Effluent Management

- Palm Oil Mill Effluent (POME) treatment system design and supply.

- Support with environmental impact assessments and compliance documentation.

- Zero-waste mill consultation.

Spare Parts, Maintenance & Upgrades

- Long-term supply of wear parts: press cages, screw shafts, digester arms, etc.

- Retrofit services for outdated palm oil mills to improve efficiency.

- Routine inspection packages for critical machinery.

Want to Build a Palm Oil Mill?

Our comprehensive palm oil equipment solutions will help you plan a complete palm oil mill layout and transform your palm fruit resources into profitable and sustainable palm oil production.

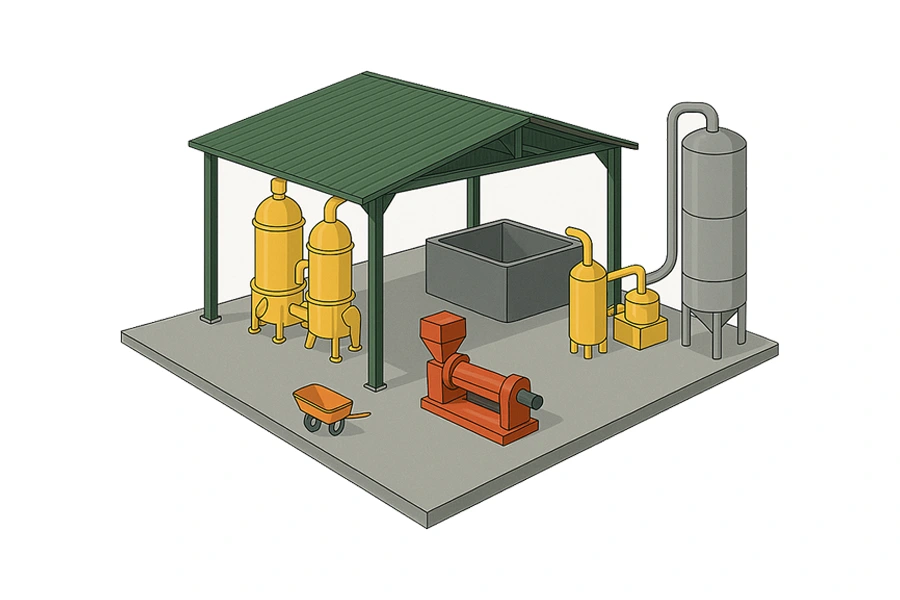

Options for Capacity in Palm Oil Mills

- Factory Area: 500 – 1,000 m²

- Production Capacity: 1 – 5 tons FFB/hour

- Number of Equipment: 8 – 12 units (Includes mini sterilizer, digester, screw press, clarification tank, nut cracker, etc.)

- Approximate Investment: $20,000 – $80,000 USD

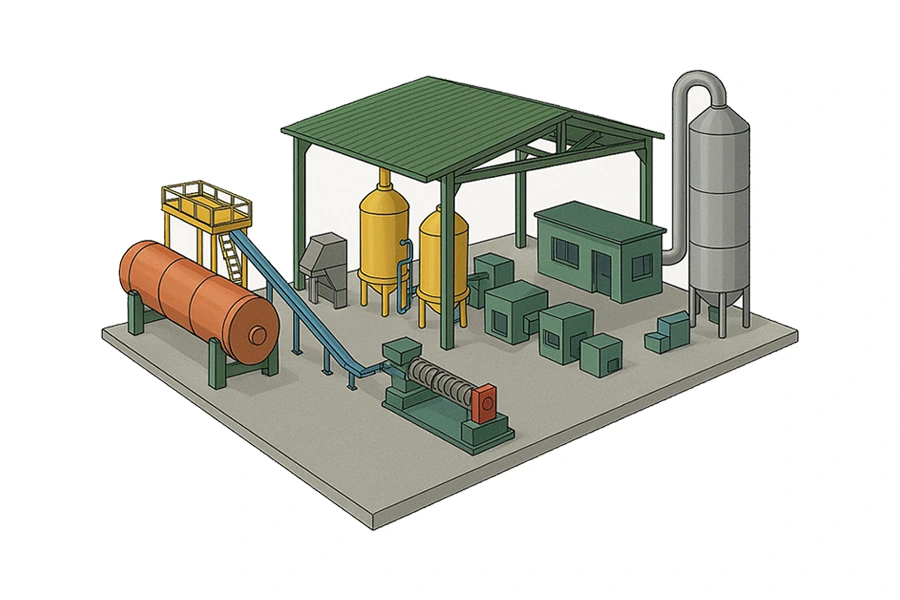

- Factory Area: 2,000 – 5,000 m²

- Production Capacity: 6 – 15 tons FFB/hour

- Number of Equipment: 15 – 25 units (Includes large horizontal sterilizer, automated thresher, twin-screw press, decanter, kernel recovery system, boiler, etc.)

- Approximate Investment: $150,000 – $500,000 USD

- Factory Area: 10,000 – 30,000 m²

- Production Capacity: 20 – 60+ tons FFB/hour

- Number of Equipment: 30 – 60+ units (Includes continuous sterilizers, automatic conveyors, full oil clarification and drying lines, advanced kernel recovery system, power plant, wastewater treatment plant, etc.)

- Approximate Investment: $1.2 million – $10 million+ USD

FAQ

What types of palm oil processing equipment do you provide?

We offer a complete range of palm oil processing equipment, including sterilizers, threshing machines, digesters, screw presses, oil clarifiers, and fiber-nut separators. Our palm oil machinery is suitable for both small-scale and industrial palm oil mills.

How can I pick the best palm oil machine for my manufacturing facility?

What is the production capacity of your palm oil processing line?

What makes a two screw oil press different from a single screw oil press?

Can your palm oil equipment process both CPO and PKO?

Do you offer turnkey palm oil mill solutions?

What materials are used in your palm oil machines?

Do you export palm oil processing machines internationally?

Is palm oil mill automation available in your systems?

What is your after-sales support for palm oil equipment?

Describe Your Project to Us

Maximize your palm oil production and quality with our complete list of production equipment, from fruit receiving to final oil pressing.