A detailed analysis of the total cost of owning a tomato processing plant, including setup, operations, infrastructure and ongoing maintenance. Whether you are a first-time investor or a seasoned food entrepreneur, understanding the cost structure is critical to successful planning.

Overview of Tomato Processing Factory Ownership

Owning a tomato processing factory includes:

- Capital investment (land, building, machines)

- Working capital (raw materials, labor, energy)

- Operating expenses (maintenance, utilities, logistics)

- Licensing and compliance

- Marketing and sales

The total cost depends on the scale of production, location, degree of automation, and type of tomato products manufactured.

Types of Tomato Processing Plants by Size

Before calculating costs, it’s important to determine the plant size:

| Plant Type | Daily Tomato Input | Estimated Capacity | Suitable For |

| Small-scale | 1–5 tons/day | 500–1,000 kg of product | Startups, rural co-ops |

| Medium-scale | 10–50 tons/day | 5–15 tons of product | Regional suppliers |

| Large-scale | 100+ tons/day | 30–50+ tons of product | Exporters, national brands |

Capital Expenditure (CAPEX)

This includes the upfront investment required to build the factory.

Land and Building

Depending on location and factory size:

| Component | Estimated Cost (USD) |

| Land (2,000–10,000 sq m.) | $50,000 – $300,000 |

| Construction of a factory and storage | $100,000 – $500,000 |

| Office, admin, canteen areas | $20,000 – $80,000 |

Total for Land & Building: $170,000 – $880,000

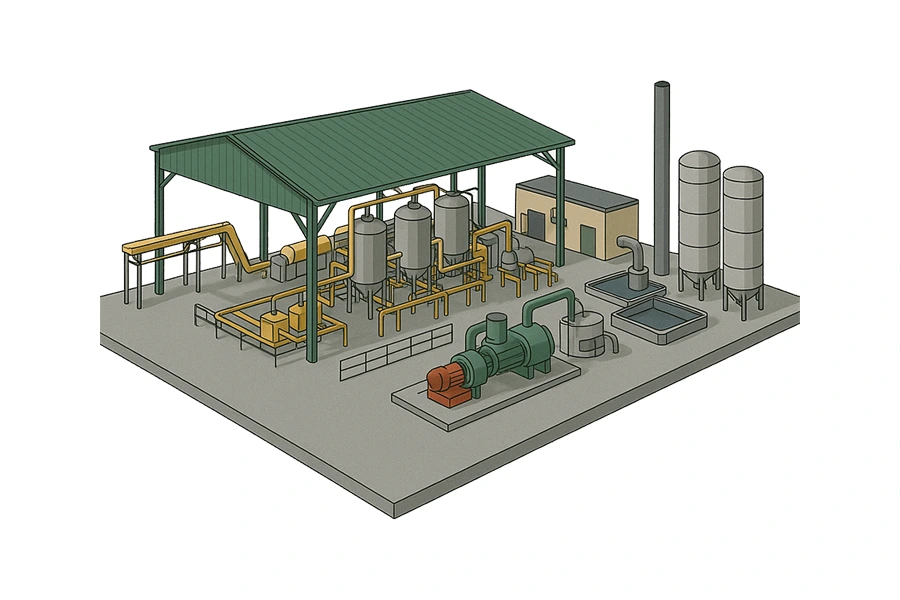

Machinery and Equipment

A processing line typically includes:

- Fruit Washing, Sorting, Lifting Monobloc

- Crushing & Transferring Pump With Thruster

- Peeling, Pulping and Refining Machine

- Scrape Type Vacuum Evaporator

- Stainless Steel Mixing Tank

- Semi-auto Capping Machine

- Pouch Forming-Filling Seaming Coding Monoblock

- Handheld Inkjet Printer

| Plant Size | Estimated Equipment Cost |

| Small-scale | $100,000 – $200,000 |

| Medium-scale | $250,000 – $600,000 |

| Large-scale | $800,000 – $2,000,000 |

Total for Machinery: Depends on size, but expect $100,000 to $2 million

Utilities and Infrastructure

- Steam boiler

- Water filtration system

- Power generator (for backup)

- Cold storage

- Wastewater treatment system

Estimated Cost: $50,000 – $200,000

Licensing, Permits & Consulting

- Food safety license (FSSAI, FDA, etc.)

- Factory registration

- Environmental permits

- Consultant and architect fees

Estimated Cost: $10,000 – $50,000

Total CAPEX Summary:

| Cost Component | Small-Scale | Medium-Scale | Large-Scale |

| Land & Building | $170,000 | $350,000 | $880,000 |

| Machinery | $100,000 | $400,000 | $1,500,000 |

| Utilities | $50,000 | $100,000 | $200,000 |

| Licenses & Setup | $10,000 | $25,000 | $50,000 |

| Total | $330,000 | $875,000 | $2.63M |

Working Capital Requirements

Working capital covers the day-to-day operational costs.

Raw Materials

Tomatoes are the primary input, usually purchased during the harvest season.

| Item | Cost Estimate (USD) |

| Tomatoes (at $70–$150/ton) | $70,000 – $300,000/year |

| Spices, salt, vinegar, thickeners | $10,000 – $50,000/year |

| Packaging materials (bottles, pouches, cans) | $30,000 – $150,000/year |

Annual Raw Material Cost: $110,000 – $500,000

Labor and Staffing

| Staff Type | Monthly Cost |

| Production staff (10–50 people) | $5,000 – $25,000 |

| Technicians & maintenance | $2,000 – $8,000 |

| Admin, sales, and marketing | $3,000 – $10,000 |

Monthly Labor Cost: $10,000 – $40,000

Annual Labor Cost: $120,000 – $480,000

Utilities (Power, Water, Steam)

- Electricity for machinery and lighting

- Water for washing and processing

- Fuel/biomass for boilers

Monthly Utility Cost: $5,000 – $20,000

Annual Utility Cost: $60,000 – $240,000

Maintenance and Consumables

- Lubricants, filters, spare parts

- Cleaning and sanitation supplies

Annual Cost: $10,000 – $50,000

Logistics and Distribution

- Transport of raw materials

- Finished product delivery

- Warehousing and cold chain (if needed)

Annual Cost: $30,000 – $100,000

Total Working Capital Summary:

| Cost Item | Annual Estimate |

| Raw Materials | $110,000 – $500,000 |

| Labor | $120,000 – $480,000 |

| Utilities | $60,000 – $240,000 |

| Maintenance | $10,000 – $50,000 |

| Logistics | $30,000 – $100,000 |

| Total Working Capital | $330,000 – $1.37M annually |

Optional Add-Ons and Future Expansion Costs

As the business grows, factory owners may need:

- Automated packaging systems: $100,000 – $500,000

- Cold storage facilities: $50,000 – $200,000

- R&D and test kitchen: $20,000 – $100,000

- Warehouse expansion or second line: $200,000 – $800,000

These upgrades increase production speed, product variety, and storage capabilities.

Example Total Cost Scenarios

| Scenario | Setup Type | CAPEX | First-Year Working Capital | Total First-Year Cost |

| Entry-Level | Small-scale (manual) | $330,000 | $330,000 | $660,000 |

| Growth Stage | Medium-scale (semi-automated) | $875,000 | $700,000 | $1.575M |

| Full-Scale | Large-scale (fully automated) | $2.63M | $1.2M | $3.83M |

Return on Investment (ROI) Consideration

Key revenue drivers:

- Selling price: $1.00 – $2.00 per kg of tomato sauce

- Yield: 1 ton of tomatoes yields ~600–700 kg of sauce

- Sales volume: 300–1,500 tons/year for medium to large factories

Example Revenue Estimation:

- Annual output: 1,000 tons of sauce

- Average selling price: $1.50/kg

- Annual revenue: $1.5 million

With a gross margin of 20–30%, the break-even point can be reached in 2–4 years, depending on cost controls and market penetration.

Additional Cost Factors to Consider

Export Compliance:

- If selling to overseas markets, you’ll need certifications like:

- BRC

- HALAL/KOSHER

- USDA Organic (if applicable)

Cost: $5,000 – $20,000/year

Marketing & Branding:

- Website and online store: $2,000 – $10,000

- Retail display promotions: $10,000 – $50,000

- Social media and influencer marketing

Annual Marketing Budget: $20,000 – $100,000

Taxes and Legal Fees:

- Income tax

- VAT or GST

- Annual audits and legal consultation

Annual Estimate: $15,000 – $40,000

Final Thoughts: Is It Worth the Investment?

Owning a tomato processing factory is capital-intensive but offers solid long-term returns. It supports agricultural value addition, provides employment, and allows entrepreneurs to tap into the growing global demand for tomato-based products.

However, the key to profitability lies in:

- Efficient cost control

- High product quality and consistency

- Strong distribution and marketing

- Strategic sourcing and season planning

Whether starting small or going full-scale, having a clear understanding of cost breakdowns is essential for planning and attracting investors or loans.

The total cost to own a tomato processing factory can range from $600,000 to over $4 million, depending on scale, level of automation, and operational strategy. While the upfront investment is significant, the return potential is promising when supported by proper planning, quality control, and market positioning.

If you’re serious about entering this industry, detailed cost modeling, feasibility studies, and phased investment plans are crucial for sustainable success.